– 64 –

10-4-3. Refrigerant Piping Connection

<Flaring>

1. Cut the pipe with a pipe cutter.

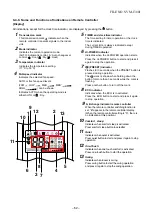

Fig. 10-4-4

2. Insert a flare nut into the pipe, and flare the pipe.

• Projection margin in flaring : A (Unit : mm)

Rigid (Clutch type)

Imperial (Wing nut type)

90˚

Obliquity

Roughness

Warp

Die

Pipe

A

Outer dia. of

copper pipe

∅

6.35

∅

9.52

∅

12.7

R410A

tool used

0 to 0.5

0 to 0.5

0 to 0.5

Conventional

tool used

1.0 to 1.5

1.0 to 1.5

1.0 to 1.5

Outer dia. of

copper pipe

∅

6.35

∅

9.52

∅

12.7

R410A

1.5 to 2.0

1.5 to 2.0

2.0 to 2.5

Fig. 10-4-5

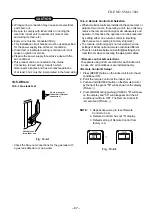

<Tightening Connection>

Align the centers of the connecting pipes and tighten

the flare nut as much as possible with your fingers.

Then tighten the nut with a wrench and torque

wrench as shown in the figure.

Fig. 10-4-6

Half union

Flare nut

Externally

threaded side

Internally

threaded side

Use a wrench

to secure.

Use a torque wrench

to tighten.

Outer dia. of copper pipe

Ø6.35 mm

Ø9.52 mm

Ø12.7 mm

Tightening torque

16 to 18 (1.6 to 1.8 kgf•m)

30 to 42 (3.0 to 4.2 kgf•m)

50 to 62 (5.0 to 6.2 kgf•m)

Flare at

indoor unit

side

Flare at

outdoor unit

side

CAUTION

• Do not apply excessive force.

Otherwise, the nut may break.

(Unit : N·m)

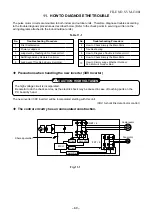

• Tightening torque of connection of flare pipe connections

The operating pressure of R410A is higher than that

of R22 (Approx. 1.6 times.) It is therefore necessary

to firmly tighten the flare pipe connecting

sections (which connect

the indoor and outdoor units)

up to the specifed tightening

torque. Incorrect

connections may

cause not only a

gas leakage, but also damage to

the refrigeration cycle.

Fig. 10-4-7

FILE NO. SVM-13001