– 39 –

FILE NO. SVM-03001

1 2 3

4

1 2 3

4

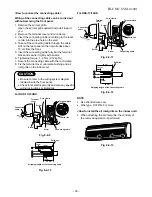

<How to connect the connecting cable>

Wiring of the connecting cable can be carried out

without removing the front panel.

1. Remove the air inlet grille.

Open the air inlet grille upward and pull it toward

you.

2. Remove the terminal cover and cord clamp.

3. Insert the connecting cable (according to the local

cords) into the pipe hole on the wall.

4. Take out the connecting cable through the cable

slot on the rear panel so that it protrudes about

15 cm from the front.

5. Insert the connecting cable fully into the terminal

block and secure it tightly with screws.

6. Tightening torque : 1.2 N·m (0.12 kgf·m)

7. Secure the connecting cable with the cord clamp.

8. Fix the terminal cover, rear plate bushing and air

inlet grille on the indoor unit.

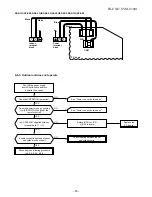

CAUTION

•

Be sure to refer to the wiring system diagram

labeled inside the front panel.

•

Check local electrical cords and also any specific

wiring instructions or limitations.

For RAS-13/10UKH

Fig. 8-4-9

Stripping length of the connecting cable

Fig. 8-4-10

Earth line

Connecting

cable

Terminal

cover

Screw

Cord clamp

Terminal block

about 15 cm

Screw

Screw

Earth line

Connecting cable

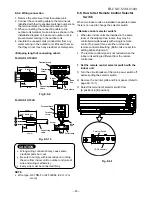

For RAS-13/10UK

Fig. 8-4-11

Stripping length of the connecting cable

Fig. 8-4-12

NOTE

•

Use stranded wire only.

•

Wire type : H07 RN-F or more

<How to install the air inlet grille on the indoor unit>

•

When attaching the air inlet grille, the contrary of

the removed operation is performed.

Fig. 8-4-13

Earth line

1 2

1 2

Connecting

cable

Terminal

cover

Screw

Cord clamp

Terminal block

about 15 cm

Screw

Screw

Earth line

Connecting cable

60 mm

10 mm

10 mm

50 mm

80 mm

10 mm

10 mm

10 mm

70 mm

50 mm