– 57 –

Shut off the

power supply once.

Turn the power supply.

Does the fan stop in

no operating status?

Control P.C. board is defective.

Replace the P.C. board.

NO

NO

NO

NO

NO

NO

NO

YES

YES

YES

YES

YES

YES

YES

Start the operation

with low fan setting

in cool operation.

Does the fan rotate?

Does AC 120 V

or higher voltage apply

to between red and black

lead of fan motor?

Does connecting

terminal, connecting

cable or power supply

cord completely?

Does not found the short

wire about connecting

cable and power cord?

Change the setting of

cooling to hight fan.

Does the cross flow

fan rotate normally?

Repair the

bearing of

the fan.

Thermal fuse operated

due to prevent

temperature rising cause

of incompleted connecting.

Shut off the power supply.

Turn on the power supply.

Does the fan speed

become higher?

Operation

stops

Motor control circuit failure

(IC30, IC03, TT10) or 12 V power

circuit failire (IC31).

Replace the P.C. board.

Is the rotation signal (DC+5 V-0 V)

output between

2

(gray lead wire)

and

3

(brown lead wire) of the motor

connector (CN11) when rotating

the cross flow fan by hand in no

operating status?

(1 pulse/one turn)

Replace the fan motor

Normal

Replace connecting

the cable (or power cord),

thermal fuse and

terminal block.

Replace the control

P.C. board.

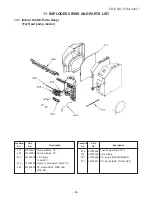

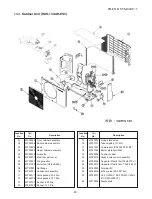

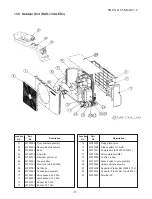

FILE NO. SVM-04017

Cooling model