– 36 –

CAUTION

• Exposure of unit to water or other moisture before installation will result in an electrical short.

Do not store in a wet basement or expose to rain or water.

• After unpacking the unit, examine it carefully for possible damage.

• Do not install in a place that can increase the vibration of the unit. Do not install in a place that can

amplify the noise level of the unit or where noise and discharged air might disturb user’s neighbors.

• To avoid personal injury, be careful when handling parts with sharp edges.

• Please read the installation manual carefully before installing the unit. It contains further important

instructions for proper installation.

For general public use

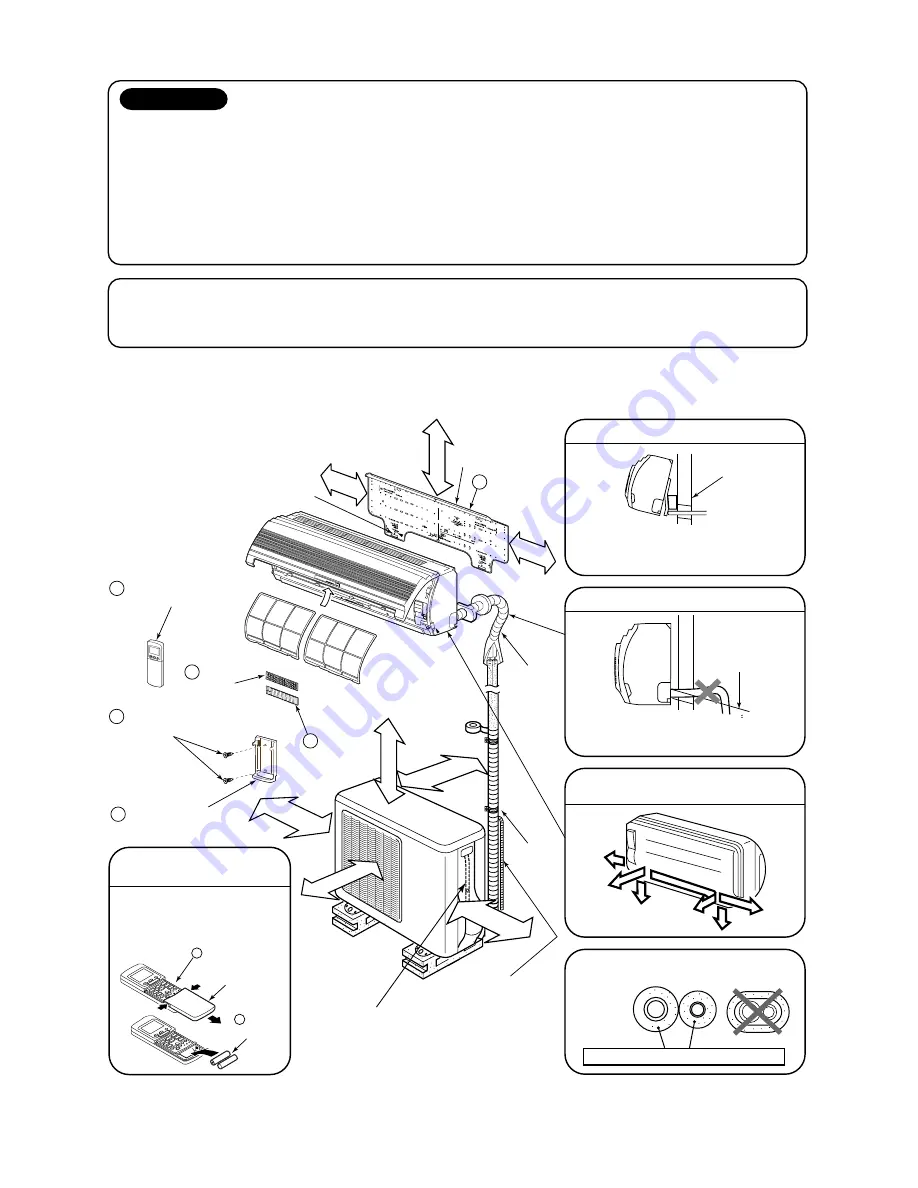

9-1-1. Installation Diagram of Indoor and Outdoor Units

Power supply cord of parts of appliance for outdoor use shall be more

than polychloroprene sheathed flexible cord (design H07 RN-F), or

cord designation 245 IEC 66. (1.5mm² or more)

Fig. 9-1-1

Air filter

(Attach to the front panel)

Shield

pipe

2 Wireless

remote controller

3

Batteries

Cover

Before installing the

wireless remote controller

• With the remote controller

cover open, load the batteries

supplied correctly, observing

their polarity.

1 Installation

plate

6 Purifying

filter

6 mm thick heat resistin gpolyethylene foam

Bottom right

Bottom left

Right

Rear left

Rear right

Left

Cut the piping hole

sloped slightly

Wall

For the rear left and left piping

Do not allow the drain hose to get slack.

Make sure to run the drain hose sloped

downward.

The auxiliary piping can be connected

the left, rear left, rear, right or bottom.

Insulation of refrigerant pipes insulates

the pipes separately, not together.

Insert the cushion between the indoor

unit and wall, and lift indoor unit for

better operation.

4 Remote controller

holder

2 Wireless

remote controller

Hook

Hook

Extension drain hose

(Option : RB-821SW)

Vinyl tape Apply

after carrying out

a drainage.

As shown in the figure,

hang power cord and

connecting cable downward,

and take out it along piping

connection port.

200mm or more

600mm or more

50mm or more

from w

all

100mm or

more from w

all

250mm or

more from w

all

170mm

or more

65mm or more

170mm

or more

Saddle

5 Zeolite

filter

8 Flat head

wood screw

Summary of Contents for RAS-13UAV-E

Page 1: ... ILE NO A02 001 SPLIT TYPE RAS 13UKV E RAS 13UAV E PRINTED IN JAPAN Mar 2002 ToMo ...

Page 73: ... 73 MCC 813 ...

Page 78: ......