– 100 –

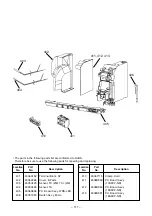

Put each leads

through the hole

Put the co

m

pressor

leads through

the hole

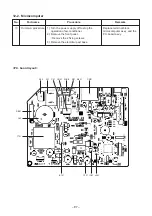

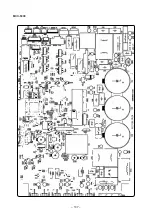

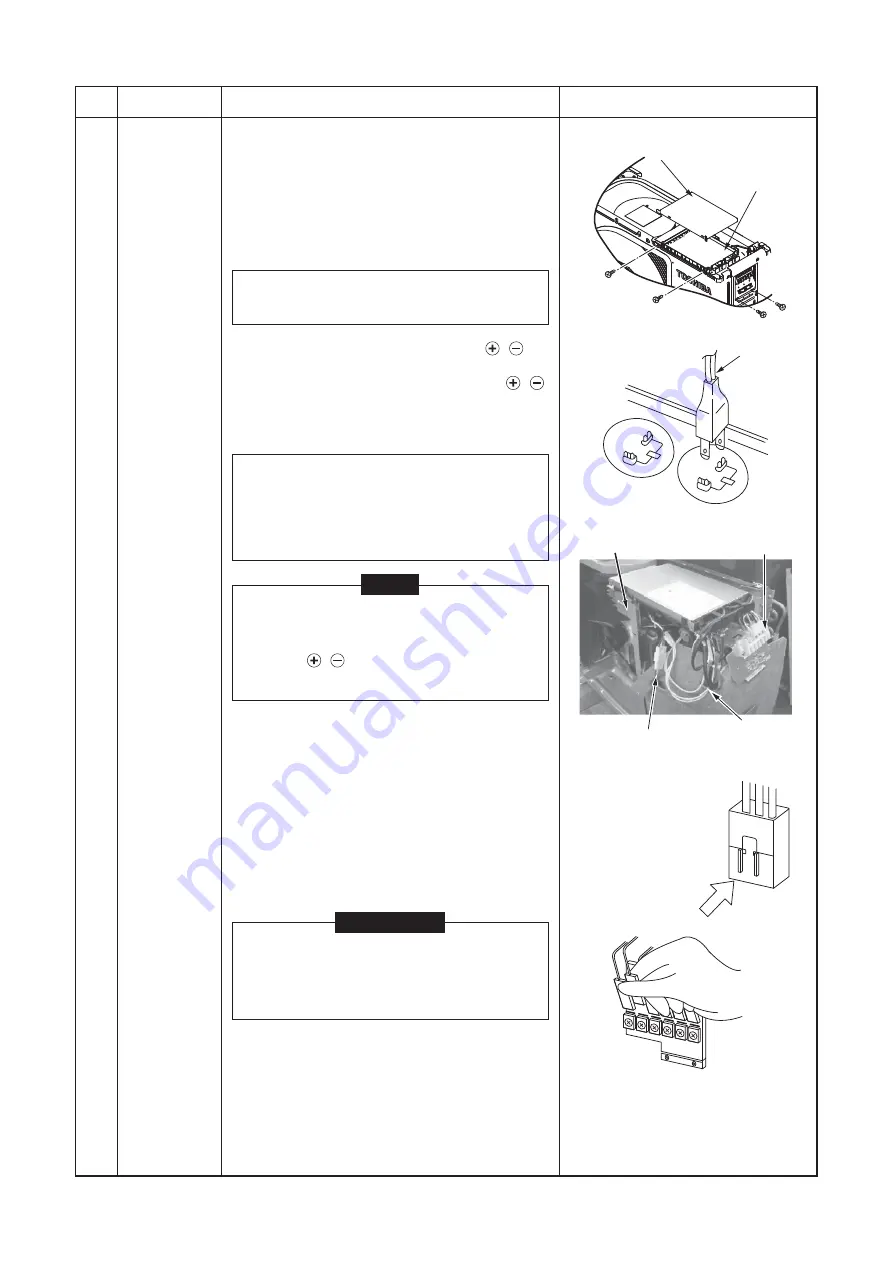

Inverter cover

P

.

C

.

b

oard

(Soldered surface)

Discharging position

(Discharging period

10 seconds or

m

ore)

Plug of

soldering

iron

A

screw

(STIT-4X8MSZ

N

)

Ter

m

inal

b

lock

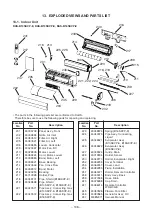

No.

Part name

Inverter

assembly

Procedure

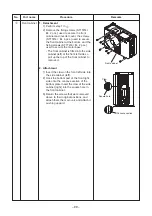

1) Perform work of item 1 in

.

2) Remove screw (ST1TØ4 × 8L 2 pcs.) of the

upper part of the front cabinet.

• If removing the inverter cover in this

condition, P.C. board can be checked.

• If there is no space above the unit, perform

work of 1 in

.

Be careful to check the inverter because

high-voltage circuit is incorporated in it.

3) Perform discharging by connecting

,

polarity by discharging resistance (approx.

100

Ω

40W) or plug of soldering iron to

,

terminals a of the C14 (printed “CAUTION

HIGH VOLTAGE” is attached.) electrolytic

capacitor (760µF) on P.C. board.

Be careful to discharge the capacitor

because the electrolytic capacitor

cannot naturally discharge and voltage

remains according to trouble type in

some cases.

NOTE

This capacitor is one with mass capacity.

Therefore, it is dangerous that a large

spark generates if short-circuiting

between

,

polarity with screwdriver,

etc. for discharging.

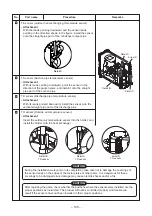

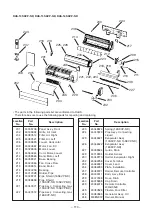

4) Remove screw (ST1TØ4 × 8L 2 pcs.) fixing

the main body and the inverter box.

5) Remove the front cabinet by performing step

1 in

, and remove the fixing screws

(ST1TØ4 × 8L) for securing the main body

and inverter box.

6) Remove various lead wires from the holder

at upper part of the inverter box.

7) Pull the inverter box upward.

8) Disconnect connectors of various lead wires.

Requirement

As each connector has a lock mecha-

nism, avoid to remove the connector by

holding the lead wire, but by holding the

connector.

Remarks

The connector is one

with lock, so remove

it while pushing the

part indicated by

an arrow.

Be sure to remove the connector by

holding the connector, not by

pulling the lead wire.