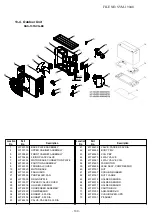

No.

Part name

Procedures

Remarks

5

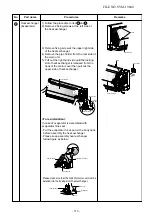

Side cabinet

1.

Side cabinet (right)

1)

Perform step 1 in

2

and all the steps in

3

.

2)

Remove the fixing screw (S

2

TØ4 × 10L 4

pcs.) used for securing the side cabinet to

the bottom plate and valve fixing panel

2.

Side cabinet (left)

1)

Perform step 1 in

2

.

2)

Remove the fixing screw (S

2

TØ4 × 10L

1 pc.) used to secure the side cabinet (left)

onto the heat exchanger.

3)

Remove the fixing screw (S

2

TØ4 × 10L

2 pcs.) used for securing the side cabinet to

the bottom plate and heat exchanger.

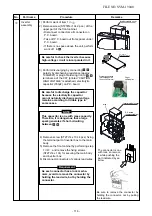

6

Fan motor

1) Perform work of item 1 of

1

and

2

.

2) Remove the f ange nut f xing the fan motor and

the propeller.

• Flange nut is loosened by turning

clockwise. (To tighten the flange nut, tur

counterclockwise.)

3) Remove the propeller fan.

4) Disconnect the connector for fan motor from

the inverter.

5) Remove the f xing screws (4 pcs.) holding by

hands so that the fan motor does not fall.

* Precautions when assembling the fan motor

Tighten the flange nut using a tightenin

torque of 4.9 N•m.

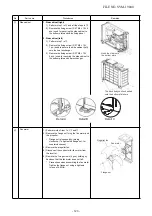

Detail A

Detail B

Detail C

Hook the claw noto

the bottom plate

The back body section hooked

onto the bottom plate here.

Propeller fan

Fan motor

Flange nut

FILE NO. SVM-19040

- 123 -