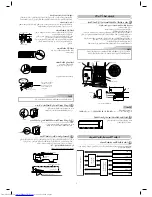

4

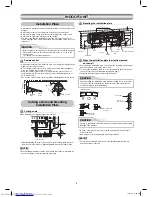

520 mm

420 mm

43

mm

80

Piping and Drain Hose Installation

* Since dewing results in a machine trouble, make sure to insulate both

connecting pipes. (Use polyethylene foam as insulating material.)

Piping and drain hose forming

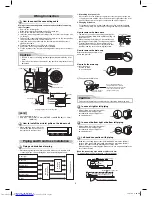

How to remove the drain cap

Clip the drain cap by needle-nose

pliers and pull out.

How to remove the drain hose

•

The drain hose can be removed by removing the

screw securing the drain hose and then pulling out

the drain hose.

•

When removing the drain hose, be careful of any

sharp edges of steel plate. The edges can injuries.

•

To install the drain hose, insert the drain hose

fi rmly until the connection part contacts with heat

insulator, and the secure it with original screw.

How to fi x the drain cap

1) Insert hexagon

wrench (4 mm)

in a center head.

In case of right or left piping

•

After scribing slits of the front panel

with a knife or a making-off pin,

cut them with a pair of nippers or

an equivalent tool.

In case of bottom right or bottom left piping

•

After scribing slits of the front panel

with a knife or a making-off pin,

cut them with a pair of nippers or

an equivalent tool.

How to install the air inlet grille on the indoor unit

•

When attaching the air inlet grille,

perform the same process as for

removal but in reverse order.

Wiring Connection

How to connect the connecting cable

Wiring of the connecting cable can be carried out without removing

the front panel.

1. Remove the air inlet grille.

Open the air inlet grille upward and pull it toward you.

2. Remove the terminal cover and cord clamp.

3. Insert the connecting cable (according to the local rule) into the pipe hole

on the wall.

4. Take out the connecting cable through the cable slot on the rear panel so

that it protrudes about 15 cm from the front.

5. Insert the connecting cable fully into the terminal block and secure it

tightly with screws.

6. Tighten fi rmly but not over 1.2 N·m (0.12 kgf·m)

7. Secure the connecting cable with the cord clamp.

8. Fix the terminal cover, rear plate bushing and air inlet grille on the indoor

unit.

1

2

3

110 mm

20 mm

10 mm

80 mm

Earth line

about 15 cm

Liquid side

Gas side

(To the forefront of fl are)

Outward form of indoor unit

R 30 mm (Use polisin (polyethylene)

core or the like for bending pipe.)

Use the handle of screwdriver, etc.

Rear right

Rear left

Bottom left

Left

Bottom right

Right

Die-cutting

front panel slit

Changing

drain hose

Piping preparation

Heat insulator

Drain hose

4 mm

Do not apply lubricating oil

(refrigerant machine oil) when

inserting the drain cap. Application

causes deterioration and drain

leakage from the plug.

Slit

Slit

CAUTION

•

Be sure to refer to the wiring system diagram labeled inside the front

panel.

•

Check local electrical cords and also any specifi c wiring instructions or

limitations.

NOTE

•

Use stranded wire only.

•

Wire type : More than 1.5 mm

2

(H07RN-F or 60245 IEC66) or 1.3 mm

2

(AWG-16)

2) Firmly insert the drain cap.

No gap

CAUTION

Firmly insert the drain hose and drain cap; otherwise, water may leak.

Left-hand connection with piping

•

Bend the connecting pipe so that it is laid within 43 mm above the wall

surface. If the connecting pipe is laid exceeding 43 mm above the wall

surface, the indoor unit may unstably be set on the wall.

When bending the connecting pipe, make sure to use a spring bender so as

not to crush the pipe.

Bend the connecting pipe within a radius of 30 mm.

To connect the pipe after installation of the unit (fi gure)

Insert a hexagon

wrench (4 mm).

Screw

Terminal cover

Terminal block

Cord clamp

Screw

Earth line

Connecting cable

Connecting cable

Stripping length of the connecting cable

1. Die-cutting front panel slit

Cut out the slit on the leftward or right side of the front panel for the left

or right connection and the slit on the bottom left or right side of the front

panel for the bottom left or right connection with a pair of nippers.

2. Changing drain hose

For leftward connection, bottom-leftward connection and rear-leftward

connection’s piping, it is necessary to change the drain hose and drain

cap.

1115551271_(01_EN).indb 4

1115551271_(01_EN).indb 4

12/17/15 3:30 PM

12/17/15 3:30 PM

Summary of Contents for RAS-18BAS Series

Page 10: ...MEMO 1115551271_ 01_EN indb C3 1115551271_ 01_EN indb C3 12 17 15 3 30 PM 12 17 15 3 30 PM ...

Page 11: ...MEMO 1115551271_ 01_EN indb C4 1115551271_ 01_EN indb C4 12 17 15 3 30 PM 12 17 15 3 30 PM ...

Page 12: ...70 L N 10 60 10 70 10 80 10 1 2 3 L N 1 3 2 A B AWG 16 RESET RESET RESET AWG 12 60245 IEC66 ...

Page 17: ... ﻣﻢ 108 ﻣﻢ 600 ﻣﻢ 28 ﻢ ﻣ 2 5 ﻣﻢ 90 ﻣﻢ 125 ﻣﻢ 320 ﻣﻢ 86 ﻣﻢ 102 Ø 8 10 A B C ...

Page 19: ......

Page 20: ...S e r i e s S e r i e s ...