Item

2. Indoor fan

motor control

Operation flow and applicable data, etc.

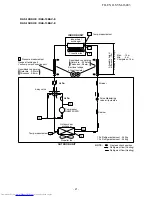

<In cooling operation>

(This operation controls the fan speed at indoor unit side.)

The indoor fan (cross flow fan) is operated by the phase-

control induction motor. The fan rotates in 5 stages in

MANUAL mode, and in 5 stages in AUTO mode, respec-

tively. (Table 1)

Description

* Symbols

UH

: Ultra High

H

: High

M+

:

M

: Medium

L+

: Low+

L

: Low

L-

: Low–

UL

: Ultra Low

SUL

: Super Ultra Low

* The fan speed broadly varies due

to position of the louver, etc.

The described value indicates one

under condition of inclining

downward blowing.

1) When setting the fan speed to L,

L+, M, M+ or H on the remote

controller, the operation is

performed with the constant

speed shown in Fig. 1.

2) When setting the fan speed to

AUTO on the remote controller,

revolution of the fan motor is

controlled to the fan speed level

shown in Fig. 2 and Table 1

according to the setup tempera-

ture, room temperature, and heat

exchanger temperature.

(Fig. 1)

(Fig. 2)

(Table 1) Indoor fan air flow rate

+2.5

Ta

[˚C]

+2.0

+1.5

+1.0

+0.5

Tsc

a

b

c

d

e

M+(W

C

)

*3

*4

*5

L(W

7

)

Air volume AUTO

L

L+

M

M+

H

W

7

(L + M) / 2

W

A

(M + H) / 2

W

D

Indication

Fan speed

Fan speed setup

COOL ON

AUTO

MANUAL

*3 : Fan speed = (M + –L) x 3/4 + L

*4 : Fan speed = (M + –L) x 2/4 + L

*5 : Fan speed = (M + –L) x 1/4 + L

(Linear approximation

from M+ and L)

RAS-07BKV-E

RAS-10BKV-E

Cooling

Heating

Cooling

Heating

Fan speed Air flow rate

(rpm)

(m

3

/hr)

Fan speed Air flow rate

(rpm)

(m

3

/hr)

Fan speed Air flow rate

(rpm)

(m

3

/hr)

Fan speed Air flow rate

(rpm)

(m

3

/hr)

WF

UH

1080

540

1080

540

1110

580

1110

580

WE

UH

H

1080

540

1080

540

1110

580

1110

580

WD

H

M+

UH

1050

520

1030

510

1080

530

1060

525

WC

M+

H

1000

490

940

450

1030

510

870

400

WB

M

M+

910

430

850

380

940

450

870

400

WA

M

M

820

370

850

380

850

390

750

325

W9

L+

820

370

730

310

850

390

750

325

W8

L+

L

L+

710

300

620

240

730

310

640

250

W7

L

L-

600

230

580

225

620

240

600

230

W6

L-

L

570

220

580

225

590

230

600

230

W5

UL

UL

L-

550

200

550

200

570

220

570

220

W4

UL

550

200

550

200

570

220

570

220

W3

SUL

SUL/SL-

540

190

520

180

550

200

520

180

W2

SUL

520

180

520

180

520

180

520

180

W1

500

170

500

170

500

170

500

170

RAS-13BKV-E

Cooling

Heating

Fan speed Air flow rate Fan speed Air flow rate

(rpm)

(m

3

/hr)

(rpm)

(m

3

/hr)

WF

UH

1200

620

1200

620

WE

UH

H

1200

620

1200

620

WD

H

M+

UH

1170

600

1080

530

WC

M+

H

1120

560

1020

500

WB

M

M+

1010

500

960

470

WA

M

M

900

420

960

470

W9

L+

900

420

840

380

W8

L+

L

L+

770

340

720

305

W7

L

L-

640

250

660

265

W6

L-

L

620

240

660

265

W5

UL

UL

L-

600

230

600

230

W4

UL

600

230

600

230

W3

SUL

SUL/SL-

560

180

520

180

W2

SUL

520

180

520

180

W1

500

170

500

170

Fan speed

level

Mode

Cool

Heat

DRY

Fan speed

level

Mode

Cool

Heat

DRY

FILE NO. SVM-16003

- 29 -