4

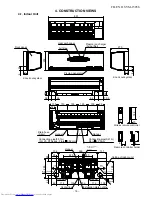

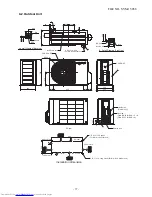

-2. Outdoor Unit

320

306

30

Z View

600

A detail Drawing (Back leg)

320

306

2- 11 x 14 Hole

(For

10 anchor bolt)

B Detail Drawing (Front leg)

Ø

25 Drain outlet

FAN-GUARD

COVER-PV

Liquid side

(Flare Ø 6.35)

Gas side

(Flare Ø 9.52 for RAS-10, 13)

(Flare Ø 12.7 for RAS-18)

Service port

2 - Ø11 x 14 Long holes (For Ø8 - Ø10 anchor bolt)

Installation dimension

Air outlel

100 or more

100 or more

600 or more

600 or more

Air intlel

Ø

Ø8 -Ø

Ø6 hole

86

Ø6 hole

Ø11x14 hole

R15

28

A

320

R5.5

36

108

125

50

137

92

54

600

32

0

90

600

90

275

290

550

Ø 436

Z

R15

50

36

320

342

69

2 - R5-5 x 17L Ushape

(For Ø 8 - Ø 10 anchor bolt)

FILE NO. SVM-15058

- 17 -

Summary of Contents for RAS-18G2ACVP-T

Page 18: ...5 WIRING DIAGRAM FILE NO SVM 15058 18 ...

Page 122: ......