FILE NO. SVM-06021

– 69 –

No.

Part name

Procedures

Remarks

2

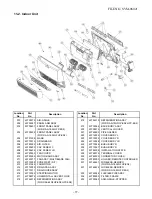

<How to remove the Front panel>

1) Remove the Air inlet grille. (

1

)

2) In case of the Drain hose is installed

through the Front panel.

: Remove the Drain band from the Front

panel.

: Cut away the Opening base for piping

from Front panel and keep parts.

3) Open 3 Cap screws and remove the

screws.

4) Remove 5 screws fixing the Front panel.

5) Remove the hooks of the Panel LED nearly

side from the Drain pan.

Front panel

(Continue)

Drain band

Drain panel

Cap screws

Front Panel

Screws