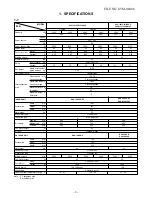

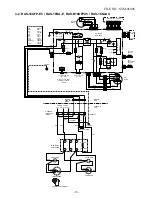

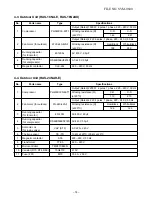

4-3. Outdoor Unit (RAS-18NA-E, RAS-18N2AX)

– 14 –

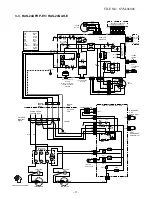

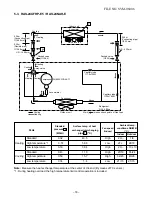

FILE NO. SVM-0600

No.

Parts name

Type

Specifications

Output (Rated) 2200 W, 2 poles, 1 phase, 220 – 240 V, 50 Hz

1 Compressor PH400X3CS-4KT1 Winding resistance (

Ω

) C-R C-S

(at 20

°

C) 1.13 2.10

Output (Rated) 42 W, 4 poles, 1 phase, 220 – 240 V, 50 Hz

2 Fan motor (for outdoor) FG-240-42A-1 Winding resistance (

Ω

) Red-Black White-Black

(at 20

°

C) 128 126

3

Running capacitor

451405L AC 450 V, 4.0

µ

F

(for fan motor)

4

Running capacitor

RS44B506K0218S AC 440 V, 50

µ

F

(for compressor)

5

Solenoid coil

VHV (STF)

AC 220 – 240 V

(for 4-way valve)

6

Thermo sensor

TE / TD

10 k

Ω

at 25

°

C / 50 k

Ω

at 25

°

C

7 Magnetic contactor

A35

220

−

240

V, 50 Hz

8 Transformer TT-05 220 – 240 V

9

Microcontroller

TMP47C840N

10

Varistor (R73, R74, R86)

15G471K

470 V

11

Fuse (F01)

MT3

T6.3 A, 250 V

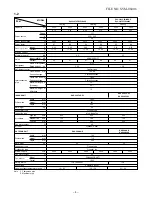

4-4. Outdoor Unit (RAS-24NAH-E)

No.

Parts name

Type

Specifications

Output (Rated) 1500 W, 2 poles, 1 phase, 220 – 240 V, 50 Hz

1 Compressor PH340X3C-4KT1 Winding resistance (

Ω

) C-R C-S

(at 20°C) 1.46 2.47

Output (Rated) 42 W, 6 poles, 1 phase, 220 – 240 V, 50 Hz

2 Fan motor (for outdoor) WLF-240-42A-1 Winding resistance (

Ω

) Red-Black White-Black

(at 20°C) 188 289

3

Running capacitor

451205L AC 450 V, 2.0

µ

F

(for fan motor)

4

Running capacitor

RS44B506U0218S AC 440 V, 50

µ

F

(for compressor)

5

Magnetic contactor

CLK-26J

220 – 240 V, 50 Hz