High Wall, Heat Pump Type

Service Manual

60

Toshiba

9-3. Installation of Indoor

Unit

9-3-1. Installation Location

• A place which provides enough space around the

indoor unit as shown in the diagram.

• A place where there are no obstacles near the air

inlet and outlet.

• A place which allows easy installation of the piping to

the outdoor unit.

• A place which allows the front panel to be opened.

• The indoor unit shall be installed so that the top of the

indoor unit is positioned at least two m high.

Also, avoid putting anything on the top of the indoor

unit.

Remote controller

• Should be placed where there are no obstacles,

such as curtains, that may block the signal.

• Do not install the remote controller in a place

exposed to direct sunlight or close to a heating

source, such as a stove.

• Keep the remote controller at least 1 m away from

the nearest TV set or stereo equipment. (This is

necessary to prevent image disturbance or noise

interference.)

• Do not install near high-frequency devices or

wireless devices.

• The location of the remote controller should be

determined as shown below.

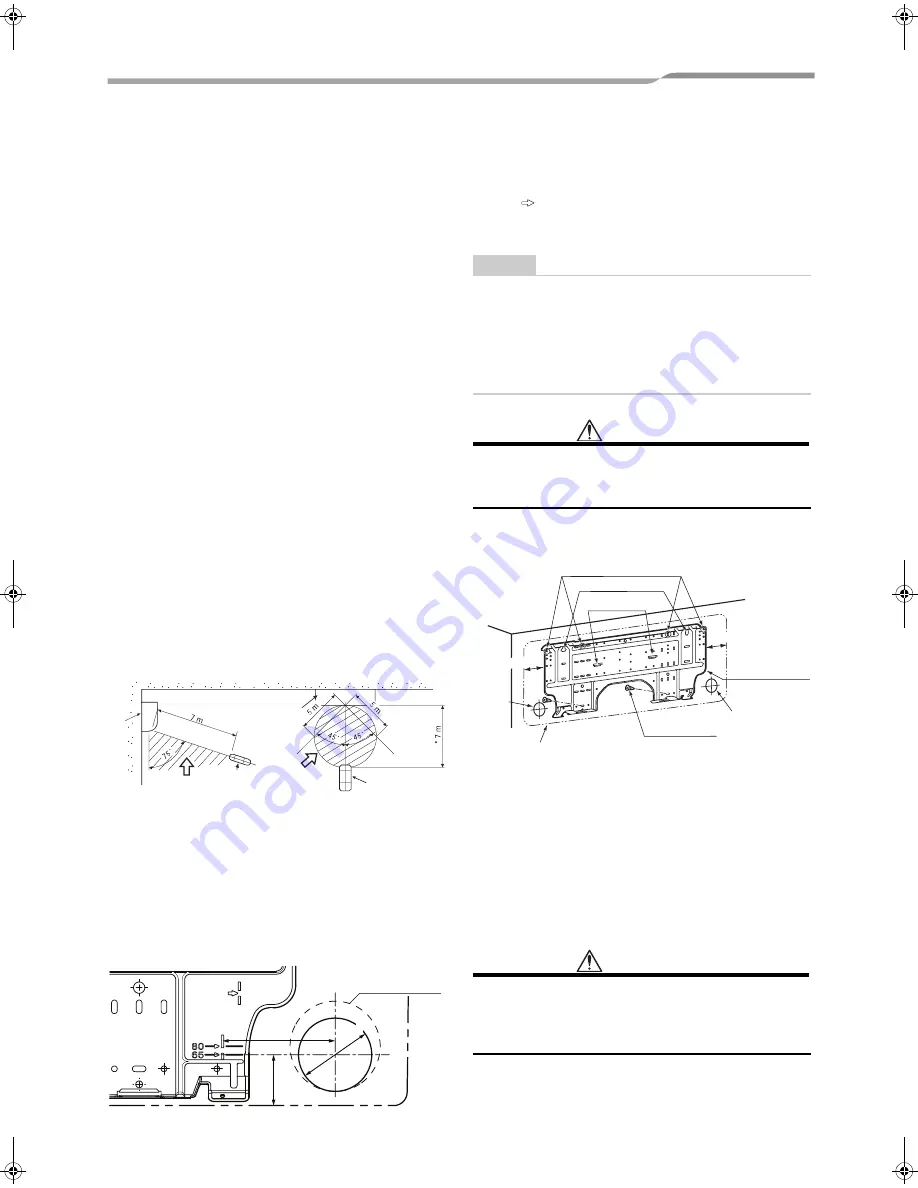

9-3-2. Drilling and Mounting

Installation Plate

Drilling

When installing the refrigerant pipes from the rear.

1) Decide the installation plate mounting position

on the wall.

2) Mark the corresponding pipe hole wall

positions according to the positioning marks (

) on the installation plate.

3) Drill the pipe holes (Dia. 65 mm or Dia. 80 mm)

slightly slanted downward to the outside.

NOTE

• When drilling into a wall that contains a metal lath,

wire lath or metal plate, be sure to use a pipe hole

brim ring sold separately.

• The unit is designed to enable installation using

holes of 65 mm in diameter. However, if installation

is difficult, make holes that are 80 mm in diameter.

CAUTION

Completely fill in the gaps in the pipe holes with

noncombustible material (such as putty) to prevent

condensation and fire in the casing.

Mounting the installation plate

Mounting the installation plate directly on a

wall

1) Securely fit the installation plate onto the wall

by screws with the upper and lower catches.

2) To mount the installation plate on a concrete

wall use anchor bolts. Drill the anchor bolt

holes as illustrated in the above figure.

3) Place the level at the top end of the installation

plate, and check that the plate is horizontal.

CAUTION

When installing the installation plate with mounting

screws, do not use anchor bolt holes. Otherwise the unit

may fall down and result in personal injury and property

damage.

Indoor unit

(Top view)

(Side view)

Remote

controller

Reception

range

Remote controller

Indo

or

un

it

*: Axial distance

Reception

range

Pipe

hole

Dia. 80 mm

100 mm

45 mm

Di

a.

65

m

m

150 mm from

unit edge

100 mm to pipe

hole center

100 mm

100 mm

Anchor bolt holes

Indoor unit

Pipe hole

Pipe hole

[5] Mounting screw

[1] Installation plate

Positions recommended for

securing the screws (4 places)

Level (magnetic-backed)

holder

+00A08-010_01EN_SVM_HighWallHeatPump.book Page 60 Wednesday, March 4, 2009 11:22 AM