– 27 –

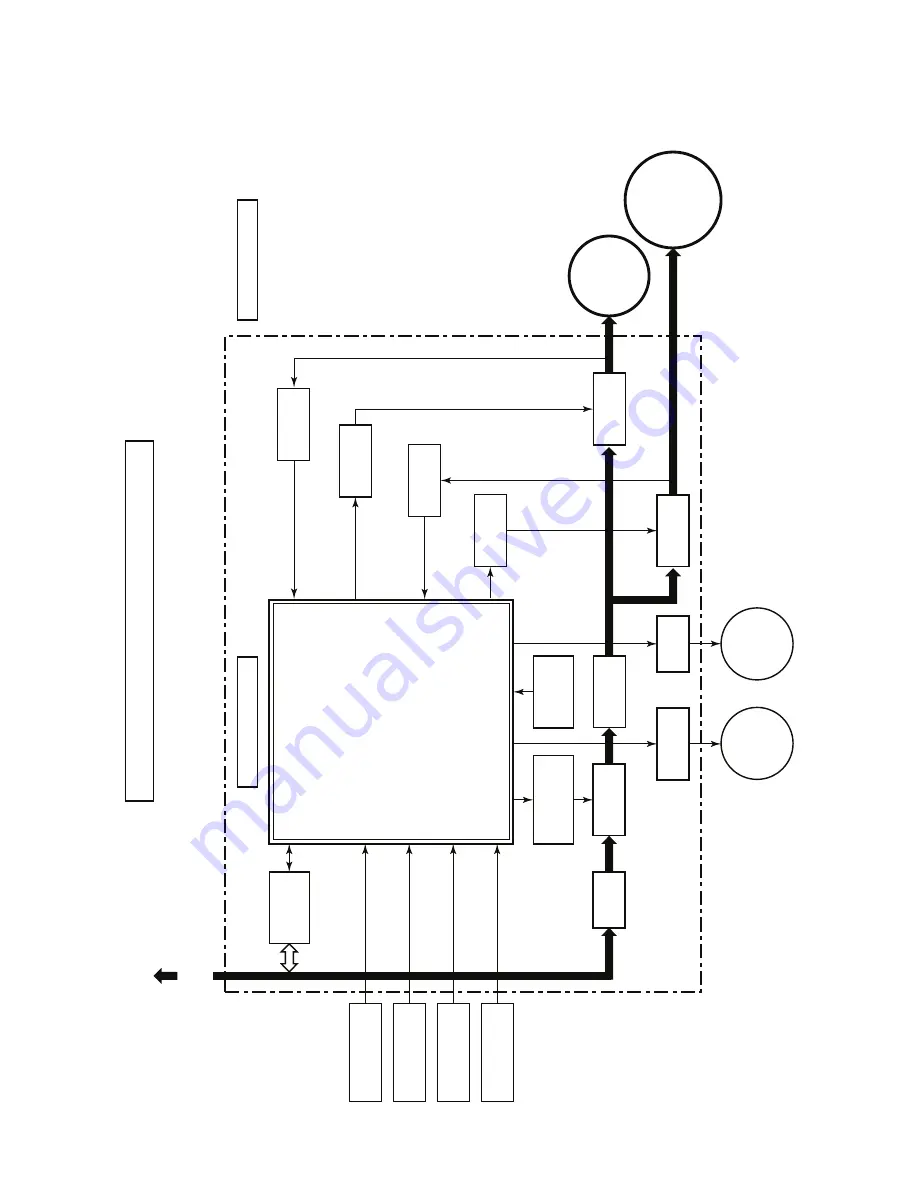

8-2. Outdoor Unit (Inverter Assembly)

220–240 V

~

50Hz

MICR

O-COMPUTER BLOCK DIA

GRAM

D

ri

v

e

r

c

ir

c

u

it

o

f

P

.M

.V

.

Indoor unit

send/receive

circuit

R

e

la

y

c

ir

c

u

it

N

o

is

e

F

ilt

e

r

C

o

n

v

e

rt

e

r

(AC

→

DC)

C

lo

c

k

fr

e

q

u

e

n

c

y

4

M

H

z

H

ig

h

P

o

w

e

r

fa

c

to

r

C

o

rr

e

c

tio

n

c

ir

c

u

it

In

p

u

t

c

u

rr

e

n

t

s

e

n

s

o

r

• PWM synthesis function

• Input current release control

• IGBT over-current detect control

• Outdoor fan control

• High power factor correction control

• Inverter output frequency control

• A/D converter function

• P.M.V. control

• Discharge temp. control

• 4-way valve control

• Signal communication to indoor unit

P.M.V.

: Pulse Motor Valve

M.C.U. : Micro Control Unit

M.C.U

For INDOOR UNIT

4-way valve

P.M.V.

Inverter

(DC

→

AC)

Gate drive

circuit

Gate drive

circuit

Inverter

(DC

→

AC)

H

e

a

t

e

x

c

h

a

n

g

e

r

temp.sensor (TE)

Suction temp.

sensor (TS)

Outdoor air

te

m

p

.

s

e

n

s

o

r

(T

O

)

Discharge

te

m

p

.

s

e

n

s

o

r

(T

D

)

Outdoor

Fan motor

220

−

230V ~60Hz

MCC5009 (P

.C.B)

OUTDOOR UNIT

Current

detect

Current

detect

Compressor

Summary of Contents for RAS-18SAV-E

Page 17: ... 17 ...