FILE NO. SVM-04032

– 69 –

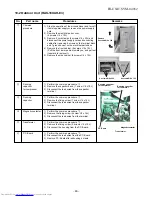

9-7. Troubleshooting for Wiring (Interconnect Cable and Serial Signal Wire)

9-7-1. Outdoor unit does not operate.

<Inspection procedure>

(1) Is the voltage between

2

and

3

of the indoor terminal block varied?

(2) Are signals from the indoor unit to the outdoor unit transmitted correctly based upon the following diagram?

NOTE:

•

Measure the voltage for 2 minutes and 30 seconds after starting the unit.

•

Prepare a diode for checking.

Fig. 9-7-1

9-7-2. Outdoor unit stops a while after starting the unit.

<Confirmation procedure> Select one of 3 cases below and follow the procedure.

(1) The outdoor unit stops between 10 and 20 minutes passed after starting and it takes 10 minutes or more to

restart the unit.

(2) The outdoor unit stops once, it would not operate until the power is turned on again.

(3) The outdoor unit stops between 10 minutes to 1 hour after starting and a check code is indicated on the

remote control. (Check code 03-1E : Refer to Table 9-4-1.)

2

1

3

Red

White

S5277G

Terminal block

Tester

S5277G or equivalent

(G or J type)

(Diode with rated voltage of

400V or more is acceptable.)

Gas has a low circulation.

Measure gas pressure.

Gas shortage

Gas leak

Pipe clogging

Refer to 9-6-3 “Compressor does not operate”.

Compressor is turned off and on automatically by thermo sensor

(Heating and Cooling Model) or thermostat (Cooling only Model).

For Heat pump model

Terminal block on indoor side

2

1

3

Red

White

Terminal block

Tester

Normal condition : Equal 220Vac

Abnormal condition : Equal 0V

For Cooling only model

Terminal block on indoor side

Normal condition : Voltage varied between DC15V and 60V.

Abnormal condition : Voltage does not vary.