– 44 –

FILE NO. SVM-02009

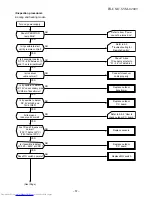

8-6. How to Set Remote Control Selector

Switch

When two indoor units ae installed in seperated rooms,

there is no need to change the selector switch.

<Remote control selector switch>

•

When two indoor units are installed in the same

room or the adjacent two rooms, they may be

controlled simultaneously with a single remote

control. To prevent this, set either unit and its remote

control to B setting. (Both units are set to A setting

before shipment.)

•

The remote control signal is not recived when the

indoor unit setting is different from the remote

control one.

1. Set the remote control selector switch with the

indoor unit.

1) Turn the circuit breaker of the main power switch off

before setting the selector switch.

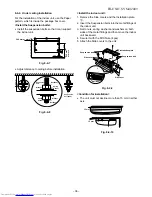

2) Remove the Air inlet grille. (Refer to page 35, 8-4-2)

Fig. 8-6-1

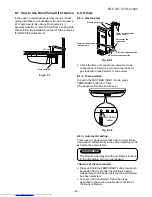

3) Select the terminal of selector switch from [A

position] to [B position].

Fig. 8-6-2

REMOCON

INST

ALL

A

C

B

F

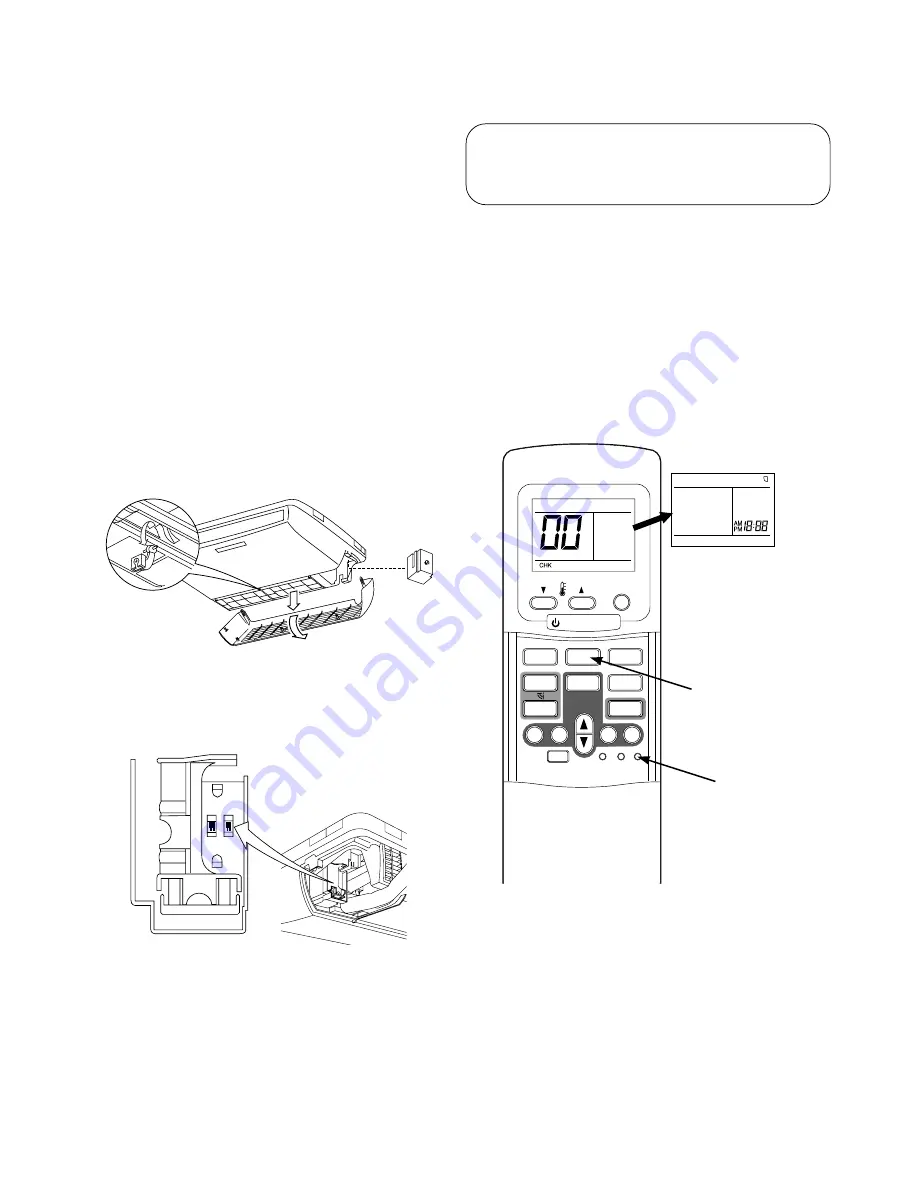

2. Set the remote control selector switch with the

remote control

[B] is indicated on the liquid crystal display when

setting remote control selector switch to B. [A] is not

indicated on the display even if the selector switch

is set to A.

1) Load the remote control with the batteries.

2) Press the [CHECK] button using something with

sharp point. (The preset temperature on the remote

control changes to [00].)

3) Press the [MODE] button while pressing the

[CHECK] button, [B] is indicted at the right of the

present temperature display.

•

To reset the switch to the [A] setting, press the

[MODE] button again while pressing the [CHECK]

button.

Fig. 8-6-3

3. Confirm that the indoor unit can operate with the

new setting.

PRESET

FAN

MODE

Hi-POWER

ON

OFF

SET

CLR

ECO

AUTO

TIMER

CLOCK CHECK

RESET

FILTER

FIX

SWING

MEMO

START/STOP

A

B

A

B

[MODE] button

[CHECK] button