–

43

–

4. DRY OPERATION (COOLING ONLY)

For dehumidification, a moderate cooling performance is controlled automatically.

1. Push

MODE : Select Dry

.

2. Push

TEMP

MODE : Set the desired temperature.

5

. Hi POWER OPERATION

To automatically control room temperature and airflow for faster cooling or heating operation

(except in DRY and FAN ONLY mode)

Push

Hi-POWER : Start and stop the operation.

6

. ECO OPERATION

To automatically control room to save energy (except in DRY and FAN ONLY mode)

Push

ECO : Start and stop the operation.

Note:

Cooling operation; the set temperature will increase automatically 1 degree/hour for 2 hours

(maximum 2 degrees increase). For heating operation the set temperature will decrease.

7

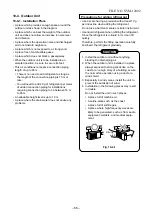

. TEMPORARY OPERATION

In case of the misplaced or discharged remote controller

• Pushing the RESET button, the unit can start or stop

without using the remote controller.

• Operation mode is set on AUTOMATIC operation, preset

temperature is 24°C and fan operation is automatic speed.

8

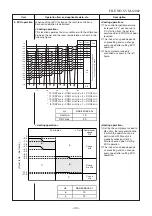

. TIMER OPERATION

Daily

timer allows the user to set both the ON and OFF timers and will be activated on a daily basis.

Setting

Daily

Timer

• During the

daily

timer is activation, both arrows ( or ) are indicated.

1

2

3

Setting the ON Timer

Push

ON

: Set the desired ON timer.

Push

SET

: Set the timer.

Push

CLR

: Cancel the timer.

Setting the OFF Timer

Push

OFF

: Set the desired OFF timer.

Push

SET

: Set the timer.

Push

CLR

.

1

2

Push

ON

: Set the ON timer.

Push

OFF

: Set the OFF timer.

3

4

Push

SET

.

Push

SET

button during the

( or ) mark flashing.

FILE NO. SVM-12002