FILE NO. SVM-10049

–

70

–

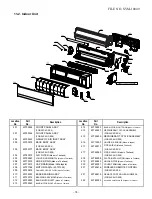

No.

Part name

Fan motor

Procedures

1) Follow to the procedure

till item

.

2) Loosen the set screw of the cross flow fan.

3) Remove two fixing screws of the motor

cover

and them remove the motor cover.

4) Remove two more fixing screws of the

motor band and remove the motor band.

Remarks

5) Pull the fan motor outward.

Set screw

Two screws on

motor band

Two screws on

motor cover

p