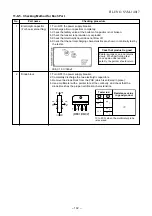

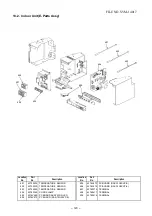

Bearing

1) Follow to the procedure in the item

and -

2) Remove 2 fixing screws from the

Base bearing assembly, then remove

Base bearing assembly from the main unit.

<Caution at assembling>

- If the bearing is out from the housing,

push it into the specified position and then

incorperate it in the main body.

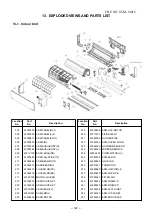

No.

Part name

Work procedure

Remarks

10

Bearing

Bearing base

Base bearing assembly

6

8

9

Fixing screw

Fixing screw

−

1

11

–

FILE NO. SVM-1

401

7

-

1