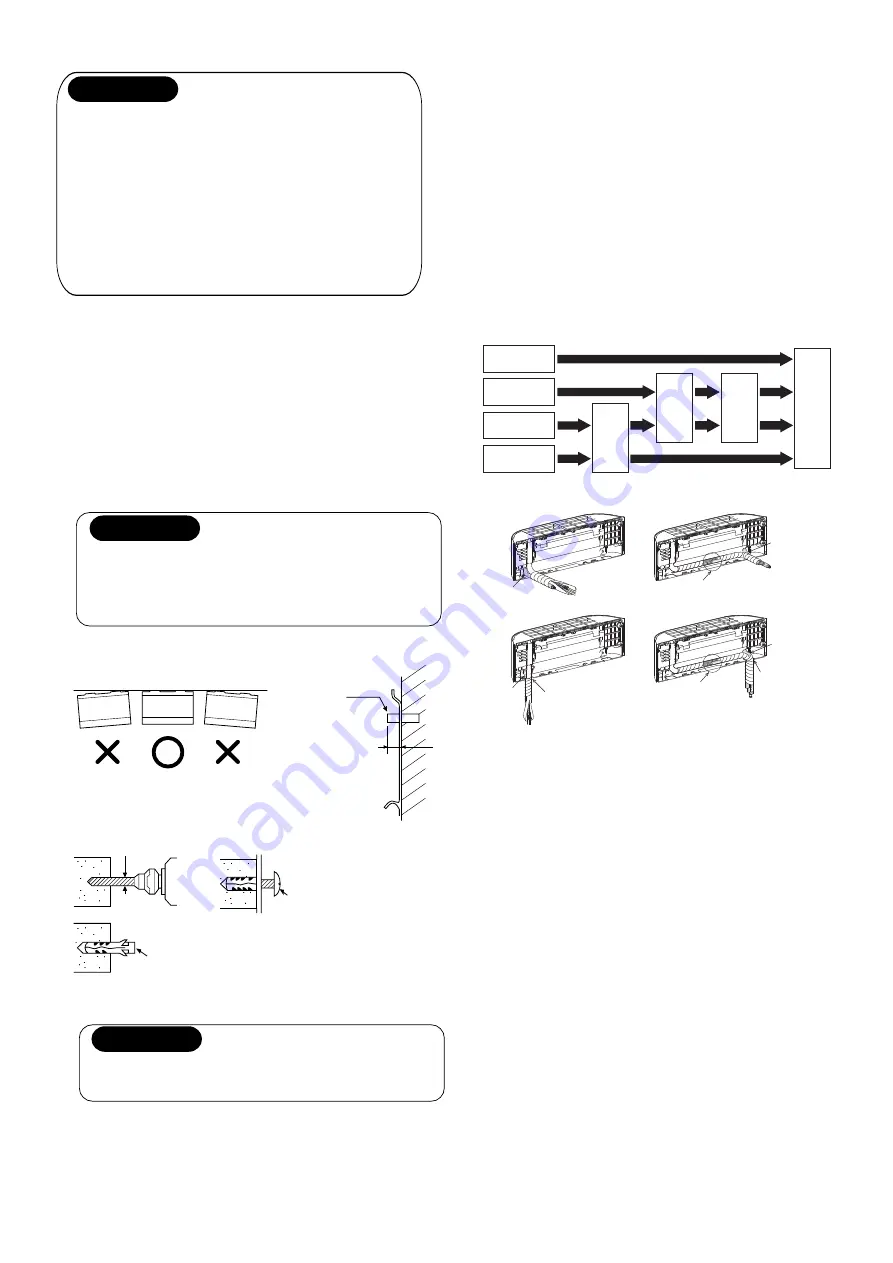

<When the installation plate is directly mounted on

the wall>

1. Securely fit the installation plate onto the wall by

screwing it in the upper and lower parts to hook up

the indoor unit.

2. To mount the installation plate on a concrete wall

with anchor bolts, utilize the anchor bolt holes as

illustrated in the above figure.

3. Install the installation plate horizontally in the wall.

CAUTION

Fig. 10-3-

5

Fig. 10-3-

6

Projection

15 mm or less

Clip anchor

(local parts)

5 mm dia. hole

Anchor

bolt

CAUTION

Failure to firmly install the unit may result in

personal injury and property damage if the unit falls.

NOTE:

•

Secure four corners and lower parts of the

installation plate with 4 to 6 mounting screws to

install it.

When installing the installation plate with a

mounting screw, do not use the anchor bolt hole.

Otherwise the unit may fall down and result in

personal injury and property damage.

Installation plate

<Keep horizontal direction>

•

In case of block, brick, concrete or similar type

walls, make 5 mm dia. holes in the wall.

•

Insert clip anchors for appropriate mounting

screws

.

Mounting

screw

∅

4

mm

x 25

s

s

s

s

s

6

6

10-3-

3

. Piping and drain hose installation

<Piping and Drain Hose Forming>

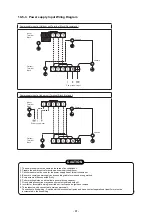

Fig. 10-3-

7

•

Since dewing results in a machine trouble,

make sure to insulate both the connecting

pipes. (Use polyethylene foam as insulating

material.)

•

The connection of pipes can be installed in the

following directions.

1.

Die-cutting

Front panel slit

•

Cut out the slit on the bottom left or bottom

right side of the Front panel for the bottom left

or bottom right connection with a coping saw

or an equivalent tool.

2.

Changing drain hose

•

The factory default of the drain hose is

installed on the right side.

•

For bottom-leftward connection and rear

leftward connection’s piping, it is necessary to

change the drain hose and drain cap.

CAUTION

•

If have curtain rails, window cornice or other

objects, allow space from the indoor unit should

be 45 mm or more.

•

If allow space is less than 45 mm, this can affect

the opening and closing of the air inlet grille and

the horizontal louver.

•

However, there should be no objects in the air

outlet position.

It will block the air fl ow direction and drop

performance.

3. Cutting and welding pipes

•

For bottom-leftward connection and rear

leftward connection’s piping, refrigerant

connection must be made by brazing or

welding.

Rear right

Rear left

Bottom left

Bottom right

Die-cutting

Front panel slit

Changing

drain hose

Pipe cutting

and welding

Piping preparation

• Rear right

• Rear left

Cut pipe and welding

Drain hose

Drain hose

• Bottom right

• Bottom left

Drain hose

Drain hose

Cut out

Front panel slit

Cut out

Front panel slit

Cut pipe and welding

- 70 -