10-5-

3

.

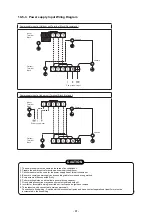

Power supply Input Wiring Diagram

1.

The power supply must be same as the rated of air conditioner.

2.

Prepare the power source for exclusive use with air conditioner.

3.

Circuit breaker must be used for the power supply line of this air conditioner.

4.

Be sure to comply power supply and connecting cable for size and wiring method.

5.

Every wire must be connected fi rmly.

6.

Perform wiring works so as to allow a general wiring capacity.

7.

Wrong wiring connection may cause some electrical part burn out.

8.

Incorrect or incomplete wiring is carried out, it will cause an ignition or smoke.

9.

This product can be connected to main power supply.

Connection to fixed wiring : A switch which disconnects all poles and has a contact separation at least 3mm must be

incorporated in the fixed wiring.

CAUTION

Power supply input at Outdoor unit Terminal Block (Recommend)

Indoor

Terminal

Block

Power supply input

Outdoor

Terminal

Block

Chassis

Chassis

Power supply input at Indoor unit Terminal Block (Optional)

Indoor

Terminal

Block

Power supply input

Outdoor

Terminal

Block

Chassis

Chassis

- 81 -