Frame

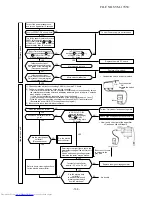

1) Follow to the procedure

-

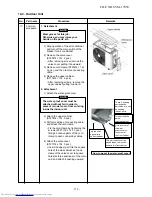

2)

Remove the fixing screws

at COVER-WIFI

1 Pcs. than take off wifi-cord out from hook

lock.

3)

Remove the Fixing screws at ASM-FRAME

(5 Pcs).

4

) Remove screw of earth lead on plate earth.

5)

Take off 5 hooks from rear side

then

remove Frame assembly.

6)

Remove a fixing screw of ground lead

then remove Earth assembly.

<How to assemble the Frame>

1) Press the top of Frame with 5 hooks of

Back-body

2) Fix Frame by 5 fixing screws.

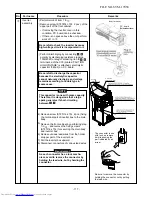

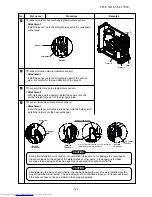

Horizontal louver

1) Remove shaft of the horizontal louver

from the back body. (First remove the

center shaft, and then remove the

other shafts.)

No.

Part name

Work procedure

Remarks

2 Screws

5 hooks from rear

Earth screw.

5

6

4

Earth

screw

1

3

Screws

1

Screw

FILE NO. SVM-17050

- 109 -