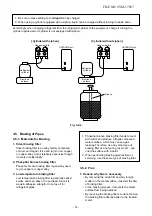

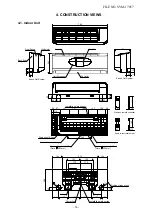

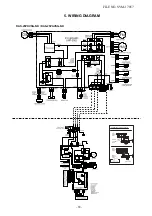

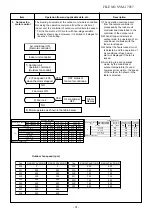

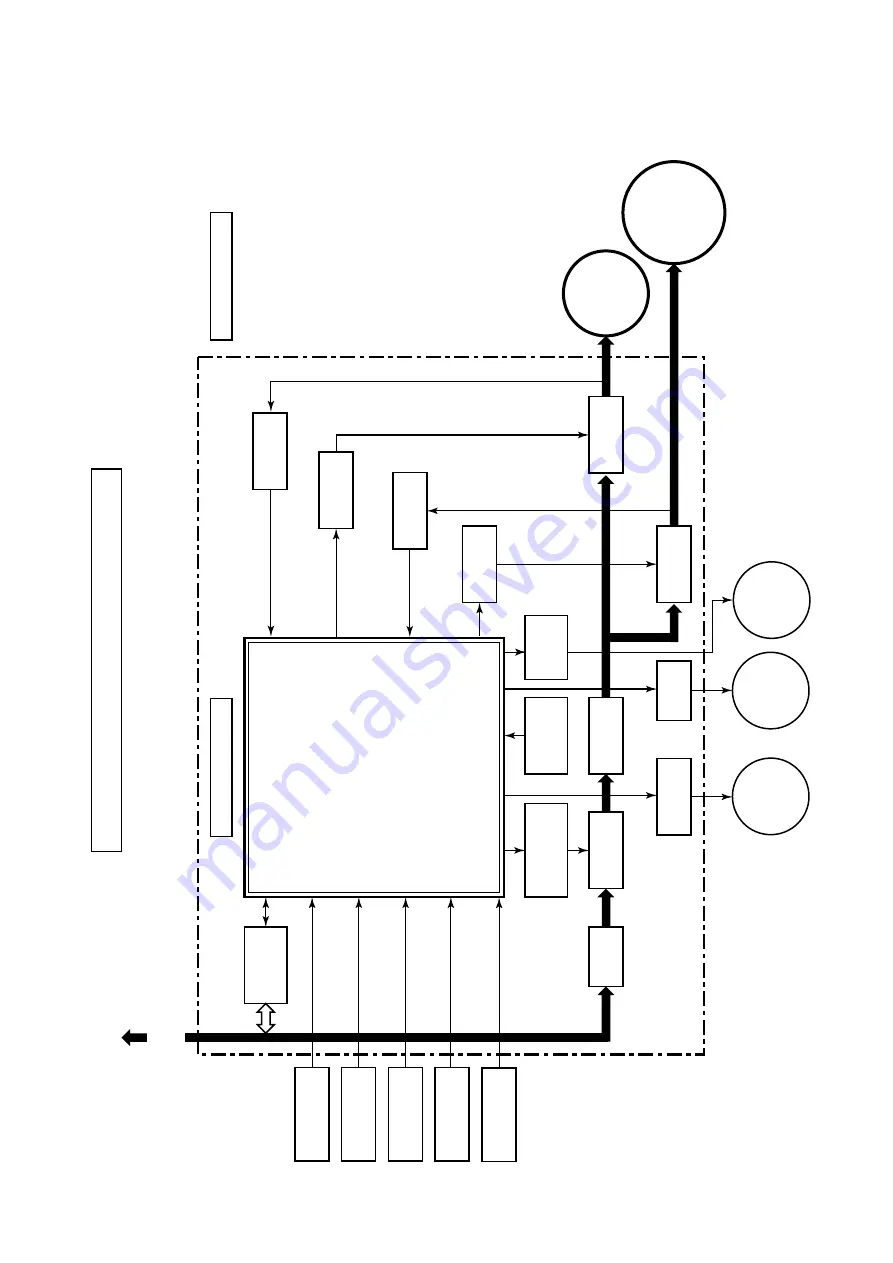

8-2. Outdoor Unit (Inverter Assembly)

220–240 V

~

50Hz

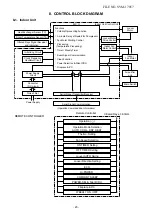

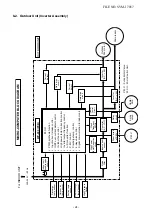

MICR

O-COMPUTER BLOCK DIA

GRAM

Driver circuit of P.M.V.

Heat exchanger temp.sensor

Suction temp.

sensor

Outdoor air temp. sensor

Discharge temp. sensor

Indoor unit send/receive

circuit

Relay circuit

Noise Filter

Converter (AC

→

DC)

Clock

frequency

4MHz

High Power

factor Correction

circuit

Input current

sensor

P.M.V.

: Pulse Motor Valve

M.C.U. : Micro Control Unit

For INDOOR UNIT

4-way valve

P.M.V.

Inverter

(DC

→

AC)

Gate drive

circuit

Gate drive

circuit

Inverter

(DC

→

AC)

Outdoor Fan motor

Compressor

WP-030 (PCB)

OUTDOOR UNIT

Current detect

Current detect

M.C.U

PWM synthesis functio

n

Input current release contr

ol

IGBT over-current detect control

Outdoor fan control

High power factor correction control

Inverter output frequency control

A/D converter function

P.M.V. control

Discharge temp. control

4-way valve control

Signal communication to indoor unit

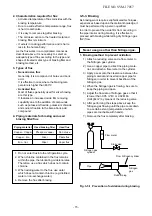

High Pressure

Switch

Heater Cord

Heater Control Circuit

FILE NO. SVM-17057

- 24 -