Table 11-8-1

(3) Check procedures

No.

1

2

3

4

5

7

Procedure

Turn off the power supply breaker

and remove the P.C. board

assembly from electronic parts

base. Remove the connecting

cables from the terminal block.

Remove the connector of the

motor and turn on the power

supply breaker.

If OPERATION indicator flashes

(once per second), it is not

necessary to check steps (1 to 3)

in the right next column.

Push [ ] button once to start the

unit. (Do not set the mode to

Fan Only or On-Timer operation.)

Shorten the restart delay timer and

start unit.

Push [ ] button once to start the

unit,

• Shorten the restart delay timer.

• Set the operation mode to COOL.

• Set the fan speed level to AUTO.

• Set the preset temperature much

lower than the room temperature.

(The unit (compressor) operates

continuously in the above

condition.)

Check points

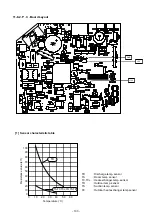

Check whether or not the fuse (F01)

or (F02) is blown.

Check power supply voltage :

1. Between No.

4

of RY01 and CN31

(AC 220–240V)

2. Between

and

of C03

3.

(DC 310–340V)

Between of C

117

and output

side of IC15 (DC 15V)

4. Between 12V and GND

5. Between 5V and GND

Check power supply voltage :

1. Between CN2

8

and

CN31

(DC 15–60V)

Check whether or not all

indicators

(OPERATION, TIMER

,

HI-POWER, ECO, Wi-Fi

)

.

are

indicated for 3 seconds and they

return to normal 3 seconds later.

1. Check whether or not the

compressor operates.

2. Check whether or not the

OPERATION indicator flashes.

Causes

Impulse voltage was applied or the

indoor fan motor short-circuited.

1.

The terminal block or the crossover

cable is connected wrongly.

2.

The capacitor (C01), line filter (L01),

resistor (R02), or the diode (DB01)

is defective.

3.

IC11, R

105, R117

and T

-

01 are

defective.

4.

IC11, IC14, C1

12

and T

-

01 are

defective.

IC51 and IC52 are defective.

The indicators are defective or the

housing assembly (CN10) is defective.

1. The temperature of the indoor heat

exchanger is extremely low.

2. The connection of the heat ex-

changer sensor is loose.

(The connector is disconnected.)

(CN62)

3. The heat exchanger sensor and the

P.C. board are defective.

(Refer to Table 11-8-1.)

4. The main P.C. board is defective.

1. The indoor fan motor is defective.

(Protected operation of P.C. board.)

2. The P.C. board is defective.

3. The connection of the motor

connector is loose.

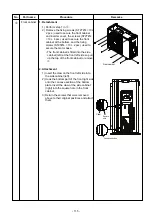

1. Check it is impossible to detect

the voltage (DC 15V) between 3

and 4 of the motor terminals.

2. The motor does not operate or

the fan motor does not rotate

with high speed. (But it is

possible to receive the signal

from the remote controller.)

3. The motor rotates but vibrates

strongly.

Connect the motor connector to

the motor and turn on the power

supply. Start the unit the following

condition.

• Set the fan speed level to HIGH.

(The unit (compressor) operates

continuously in the above

condition in No. 5.)

6

If the above condition (No. 5) still

continues, start the unit in the

following condition.

• Set the operation mode to

HEAT.

• Set the preset temperature

much higher than room tem-

perature.

1. Check whether or not the

compressor operates.

2. Check whether or not the

OPERATION indicator flashes.

1. The temperature of the indoor heat

exchanger is extremely high.

2. The connection of the heat

exchanger sensor short-circuited.

(CN62)

3. The heat exchanger sensor and the

P.C. board are defective.

(Refer to Table 11-4-1.)

4. The main P.C. board is defective

- 102 -