10-4-3. Refrigerant piping connection

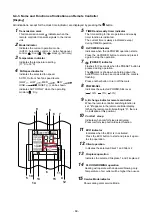

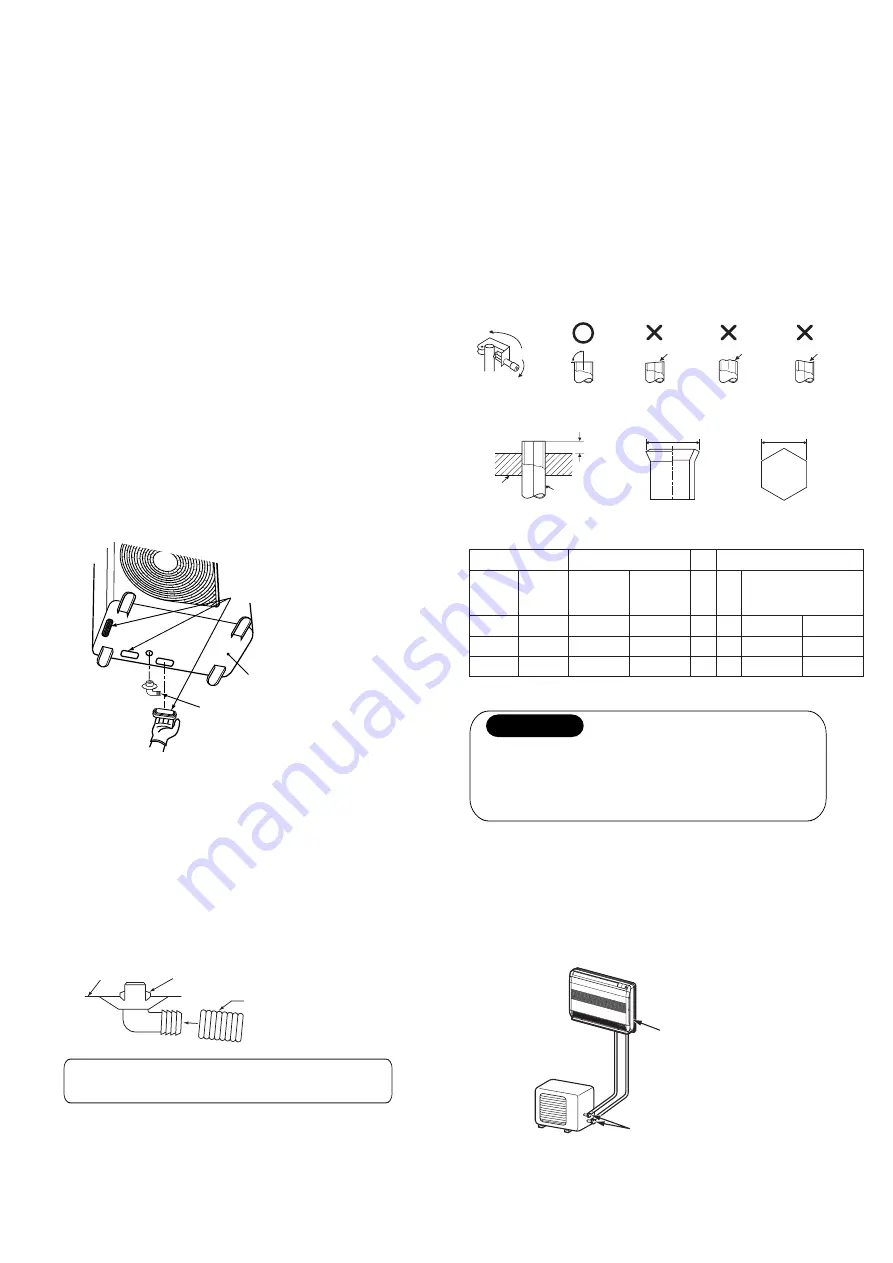

<Flaring>

1. Cut the pipe with a pipe cutter.

2. Deburr the inside of the pipe at its end.

Take steps to ensure that the removed burrs will not

enter the pipe.

3. Remove the flare nuts provided with the indoor and

outdoor units, and insert them into the pipe.

4.Flare the pipe.

The projection margin of the pipe must be checked.

5.Check that the flare has the appropriate shape.

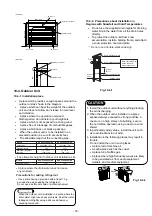

Do not use ordinary garden hose, but one can

flatten and prevent water

from draining.

2.

Install the drain nipple and a commercially available

drain hose (with 16 mm

inside diameter), and drain

off the water.

(For the position where the drain nipple is installed,

refer to the installation

diagram of the indoor and

outdoor units.)

•

Check that the outdoor unit is horizontal, and route

the drain hose at a

downward sloped angle while

ensuring that it is connected tautly.

Base plate

Drain nipple

Commercially available

drain hose

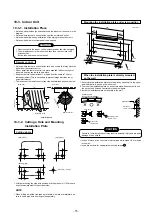

Draining the Water

•

Holes are provided on the base plate of the

outdoor unit to ensure that the

defrost water

produced during heating operations is drained

off efficiently.

If a centralized drain is required

when installing the unit on a balcony or

wall,

follow the steps below to drain off the water.

1. Proceed with water-proofing by installing the

water-proof rubber caps in

the 2 elongated holes on

the base plate of the outdoor unit.

[How to install the water-proof rubber caps]

1)

2)

Place four fingers into each cap, and insert the

caps into the water

drain holes by pushing them

into place from the underside of the base

plate.

Press down on the outer circumferences of the

caps to ensure that they

have been inserted tightly

(Water leaks may result if the caps have not been

inserted properly, if

their outer circumferences lift

up or the caps catch on or wedge against

something.)

90

°

Obliquity

Die

Pipe

A

B

C

Roughness

Warp

Pipe

A

B

Flare Nut

Outside

diameter

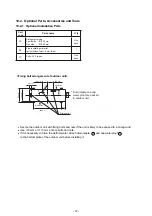

Thickness

RIDGID

(clutch type)

R32 tool

IMPERIAL

(wing nut

type)

R32 tool

C

Tighten torque

mm

mm

mm

mm

mm

mm

N

•

m

kgf

•

m

6.35

0.8

0 to 0.5

1.5 to 2.0

9.1

17

14 to 18

1.4 to 1.8

9.52

0.8

0 to 0.5

1.5 to 2.0

13.2

22

33 to 42

3.3 to 4.2

●

Do not scratch the inner surface of the fared

part when removing

burrs.

●

Flare processing under the condition of

scratches on the inner

surface of fare

processing part will cause refrigerant gas leak.

●

Tightening torque for connection of flare pipe

The

pressure of R32 is higher than R22

(Approx. 1.6 times). Therefore securely

tighten the flare pipes which connect the

outdoor unit

and the indoor unit with the

specified tightening torque

using a torque

wrench. If any flare pipe is incorrectly

connected, it may cause not only

a gas leakage but also trouble in the

refrigeration cycle.

Flare at

indoor unit side

Flare at

outdoor unit side

CAUTION

Fig. 10-

4

-

3

Fig. 10-

4

-

4

Fig. 10-

4

-

5

Base plate

Drain nipple

Water-proof rubber caps

(supplied with the outdoor unit)

- 79 -