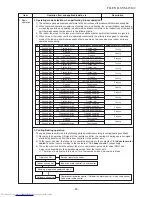

9-2. Operation Description

1. Basic operation .......................................................................................................................

49

1. Operation control ...............................................................................................................

49

2. Operating mode selection when performing 2-room operation ......................................... 5

0

3. Cooling/Heating operation ................................................................................................. 5

0

2. Outdoor fan motor control ....................................................................................................... 5

1

3. Capacity control ...................................................................................................................... 5

2

4. Current release control ........................................................................................................... 5

3

5. Winding/Coil heating control ................................................................................................... 5

4

6. Defrost control (Only in heating operation) ............................................................................. 5

4

7. Compressor protective control ................................................................................................ 5

4

8. Discharge temperature control ............................................................................................... 5

5

9. Pulse motor valve (PMV) control ............................................................................................ 5

5

9-

3

. Intermittent Operation Control for Indoor Fans of the Indoor Unit

at Thermo-off Side in Heating Operation..............................................................

5

6

10. High-pressure switch/Compressor case thermostat control .................................................... 5

5

9-4. Service switch (SW01, SW0 ) operation ...............................................................

5

6

FILE NO. SVM-15102

- 4

8

-

Summary of Contents for RAS-2M14S3AV-E

Page 31: ...4 1 Outdoor Unit 4 CONSTRUCTION VIEWS FILE NO SVM 15102 31 Unit mm ...

Page 116: ......