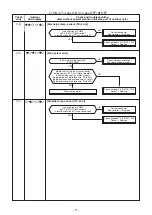

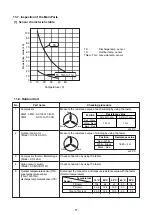

Block distinction

Operation of diagnosis function

Check

code

Block

Check

code

Cause of operation

Air

conditioner

status

Display flashing

error

Compressor drive output error.

All OFF

Flashes after

(Relation of voltage, current

error is detected

and frequency is abnormal)

8

times*.

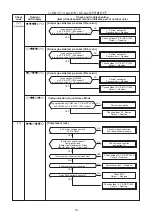

Overloading operation of

compressor caused by

over-charge refrigerant,

P.M.V. failure, etc.

Compressor failure (High

current).

1.

Check installation conditions such as

packed valve opening, refrigerant

amount and power supply (rate +10%,

both of operation and non operation

condition).

2. (In case of P.M.V. exists)

Check P.M.V. by measure the

resistance of the coil and confirm its

operation (sound of initial

operation, etc.)

3.

Observe any possibility cause which

may affect operation load of

compressor.

4.

Operate again. If compressor

operation

is failure when 20 seconds

passed

(count time from operation

starting of

compressor), replace

compressor.

*

4

or 8

times ; When first error is detected, error is count as 1 time, then once operation is stop and re-started.

After re-starting operation within 6 minutes, if same error is detected, error count is add (count become 2 times)

When error count comes 4, 8, 11 or 18 times, record error to check code. But after re-starting operation, if no

error is detected and air conditioner can operate more than 6 minutes, error count is cleared.

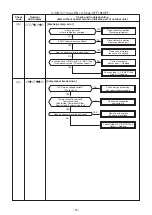

The others

Return signal of the outdoor

Indoor unit

Flashes when

(including

unit has been sent when

operates

error is detected.

compressor)

operation start. But after

continue.

Flashing stop

that, signal is stop some time.

Outdoor unit

and outdoor unit

Instantaneous power

stop.

start to operate

failure.

when the return

Some protector

signal from the

(hardware) of the

outdoor unit is

outdoor unit open

normal.

circuit of signal.

Signal circuit of indoor

P.C. board or outdoor

P.C. board is failure

in some period.

1.

Check power supply (Rate + 10%)

2.

If the air conditioner repeat operates

and

stop with interval of approx. 10

to

40

minutes.

(In case of

these

exist)

Check protector (hardware) such

as

Hi-Pressure switch,

Thermal-Relay, etc.

Check refrigerant amount, packed

valve

opening and any possibility

cause which

may affect high

temperature or high

pressure.

3.

Check operation signal of the indoor

unit

by using diode. Measure voltage

at

terminal block of the indoor unit

between No.2 and No.3 (or L2 and S)

If

signal is varied 15-60V continuously,

replace inverter P.C. board.

If signal is not varied, replace indoor

P.

C. board.

Action and Judgment

Outdoor

TE or TS sensor; abnormal.

Out of place, disconnection,

shortage, or misconnection

(TE sensor is connected to

TS connector, TS sensor is

connected to TE sensor

connector)

TE sensor; Outdoor heat

exchanger temperature

sensor

TS sensor; Suction pipe

temperature sensor

5.

Check sensors, TE, TS connection.

In

case of sensors and it’s connection

is

normal, check the inverter P

.

C

.

board

.

6.

Check 4way valve operation/position.

In case TE, TS detected temperature

relationship are different from normal

operation, “

1C

” might be detected.

- 64 -