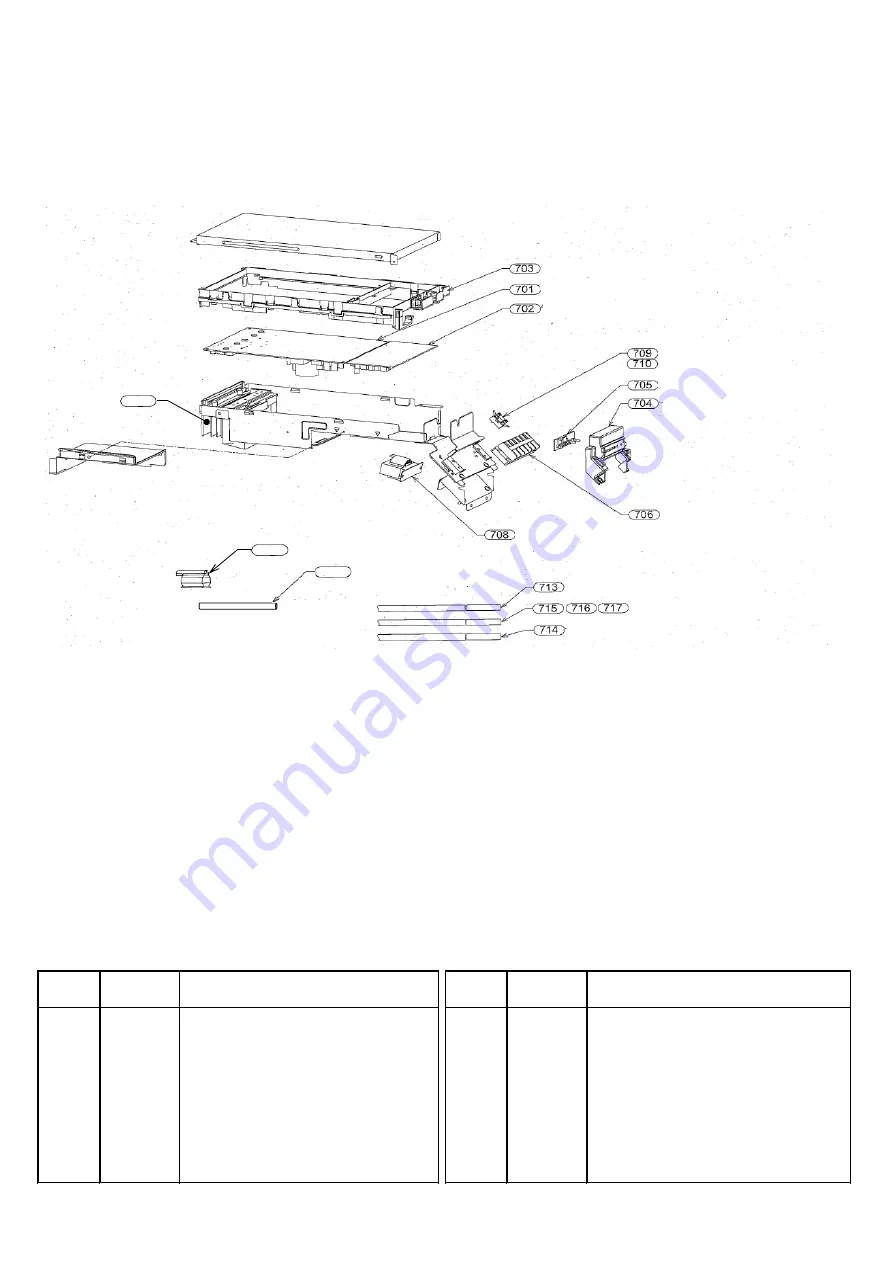

RAS-3M41U2ACVG-SG

Location

Part

Location

Part

No.

No.

No.

No.

701

43T6W473

713

43T50360

702

43T6W474

714

43T50334

703

43T61325

715

43T50361

704

43T61320

716

43T50362

705

43T6V418

717

43T50363

706

43T60423

718

43T62377

708

43T58326

719

43T63317

709

43T60426

724

43T62371

TC-SENSOR(TO)

TEMPERATURE SENSOR

SENSOR-TEMP

SENSOR-TEMP

SENSOR-TEMP

TUBE

HOLDER,SENSOR

HEAT-SINK

710

43T60425

ASM-L-PCB

PCB BOARD ASSY

BASE,PC BORAD

BASE, PC BOARD

PC BOARD ASSY

SERV-TERMINAL

REACTOR,CH-76

FUSE

FUSE HOLDER

Description

Description

719

HOLDER-SENSOR(TD)

SENSOR (TD)

SENSOR-TEMP(TGA,TGB,TGC)

TC-SENSOR (TO)

REACTOR

SERV-TERMINAL (6P)

BASE-PLATE-PC

ASM-L-PCB (CDB)MCC-1645)

ASM-L-PCB (CDB)MCC-1665

718

TUBE

BASE-PLATE-PC

ASM-L-PCB (CDB) MCC-1645

FUSE(6.3A)

FUSE-HOLDER

ASM-PCB-SERV(DS (MCC-1646)

ASM-BASE-PL-SUB

FUSE (6.3A)

FUSE-HOLDER

ASM-PCB-SERV(DS) MCC-1646

HEATSINK

724

- 90 -