– 15 –

FILE NO. SVM-06017

7-2. Description of Operation Circuit

(1) When turning on the breaker, the operation lamp

blinks. This means that the power is on (or the

power supply is cut off.)

(2) When pressing [ ] button on the

remote control, receiving beep sounds from the

indoor unit, and the next operation is performed

together with opening the vertical air flow louver.

(3) Once the operation mode is set, it is memorized in

the microcomputer so that the previous operation

can be effected thereafter simply by pressing

[ ] button.

7-2-1. Fan only operation

([MODE] button on the remote control is set

to the fan only operation.)

(1) When [FAN] button is set to AUTO, the indoor fan

motor operates as shown in Fig. 7-2-1. When

[FAN] button is set to LOW, LOW

+

, MED, MED

+

or

HIGH, the motor operates with a constant air flow.

NOTE:

*1: The values marked with *1 are calculated and

controlled by the difference in motor speed

between M+ and L–.

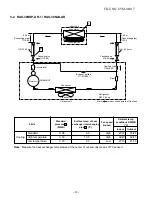

7-2-2. Cooling operation

([MODE] button on the remote control is set

to the cooling operation.)

(1) The compressor, outdoor fan and operation

display on the remote control are controlled as

shown in Fig. 7-2-2.

Fig. 7-2-2

(2) When [FAN] button is set to AUTO, the indoor fan

motor operates as shown in Fig. 7-2-3. When

[FAN] button is set to LOW, LOW+, MED, MED+ or

HIGH, the motor operates with a constant air flow.

NOTE:

*1: The values marked with *1 are calculated and

controlled by the difference in motor speed

between M+ and L–.

Fig. 7-2-3 Setting of air flow [FAN:AUTO]

(Preset temp.: 24

°

C

+2

+2.5

+3

+1.5

+1

+0.5

0

M+

*1

*1

*1

L–

(Room temp.)

–

(Preset temp.)

Preset

temp.

0.5

0

Preset

temp.

ON

ON

OFF OFF OFF ON

Compressor

4-way valve

Outdoor fan

OPERATION

display

(Room temp.)

−

(Preset temp.)

*1

*1

*1

L–

+3

+2.5

+2

+1.5

+1

+0.5

-0.5

0

M+

(Room temp.)

–

(Preset temp.)

Preset

temp.

operation cannot be set.

Fig.

7-2-1 Setting of air flo

w [FAN:AUTO]

(2)

The Hi PO

WER, ECO and COMFORT SLEEP