– 89 –

11-3. Self-Diagnosis by Remote Controller (Check Code)

1. If the lamps are indicated as shown B to E in Table 11-3-1, execute the self-diagnosis by the remote controller.

2. When the remote controller is set to the service mode, the indoor controller diagnoses the operation condi-

tion and indicates the information of the self-diagnosis on the display of the remote controller with the check

codes. If a fault is detected, all lamps on the indoor unit will flash at 5Hz and it will beep for 10 seconds

(Beep, Beep, Beep ... ). The timer lamp usually flashes (5Hz) during self-diagnosis.

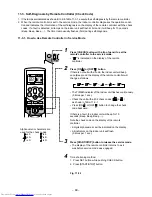

11-3-1. How to Use Remote Controller in Service Mode

TEMP

PURE

AUTO

PRESET

MODE

1.3.5.9H

CLOCK

CHECK

RESET

HiPOWER

ECO

MEMO

CLR

SET

SWING

FIX

FAN

SLEEP

ON

OFF

Press [CHECK] button with a tip of pencil to set the

remote controller to the service mode.

• “ ” is indicated on the display of the remote

controller.

Press [ON ] or [OFF ] button

If there is no fault with a code, the indoor unit will beep

once (Beep) and the display of the remote controller will

change as follows :

• The TIMER indicator of the indoor unit flashes continuously.

(5 times per 1 sec.)

• Check the unit with all 52 check codes ( to )

as shown in Table-11-3-1.

• Press [ON ] or [OFF ] button to change the check

code backward.

If there is a fault, the indoor unit will beep for 10

seconds (Beep, Beep, Beep ... ).

Note the check code on the display of the remote

controller.

• 2-digits alphanumeric will be indicated on the display.

• All indicators on the indoor unit will flash.

(5 times per 1 sec.)

Press [START/STOP] button to release the service mode.

• The display of the remote controller returns to as it

was before service mode was engaged.

Time shortening method.

1. Press SET button while pushing CHECK button.

2. Press [START/STOP] button.

1

2

3

4

Alphanumeric characters are

used for the check codes.

is 5.

is 6.

is A.

is B.

is C.

is D.

• • •

Fig. 11-3-1

Summary of Contents for RAS-3M26GAV-E

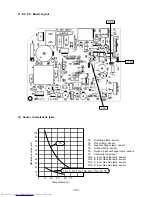

Page 121: ... 121 MCC 1438 ...

Page 122: ... 122 MCC 818 ...