Motor base

Detail A

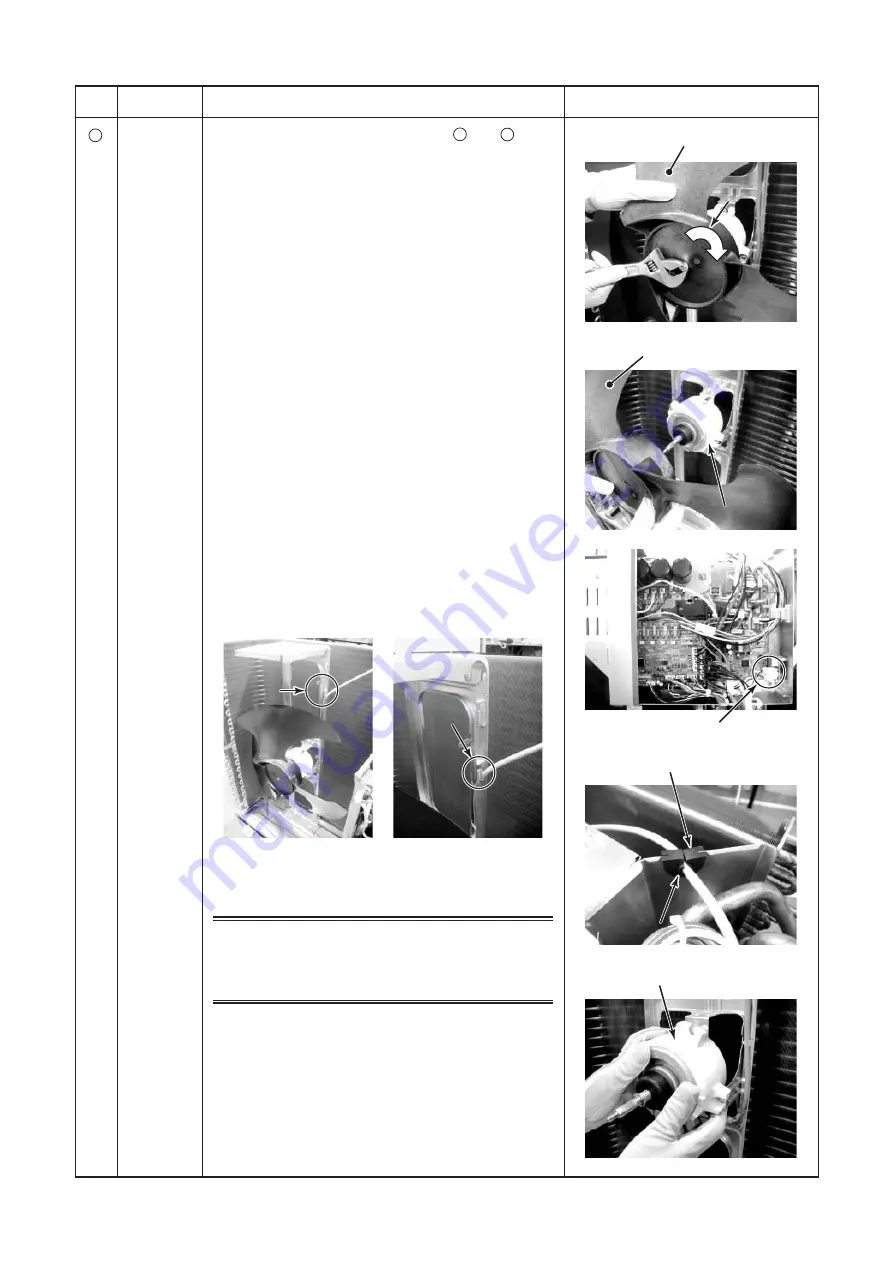

Propeller fan

Propeller fan

Loosened by

Loosened by

turning clockwise

turning clockwise

Flange nut

Flange nut

Fan motor

Fan motor

Fan motor

Fan motor relay connector

Fan motor lead fixing rubber

Detail A

Detail A

Lower groove

Lower groove

Detail A

Lower groove

Projection/Refrigerating

Projection/Refrigerating

cycle side

cycle side

Loosened by

turning clockwise

Flange nut

Projection/Refrigerating

cycle side

Fan motor

No.

8

Part name

Fan motor

Procedure

1) Perform works of Detachment 1 of

1

and

2

.

2) Take off flange nut which fixes the fan motor and

the propeller fan.

∗

The flange nut is loosened by turning it clockwise.

(To tighten the flange nut, turn it counterclockwise.)

3) Remove the propeller fan.

4) Remove the relay connector for fan motor from the

inverter.

5) Remove the fan motor lead from the fan motor

lead fixing rubber of the penetrating part of the

partition plate.

6) Take off the fixing screws (4 pcs. each) while

supporting the fan motor so that it does not fall.

∗

Caution to assembly of fan motor

• Tighten the flange nut with 4.95N•m (50kgf•cm).

• Adjust length of the fan motor lead fixing

rubber so that the slackened fan motor lead

does not come to contact with the propeller fan.

Put in the fan motor lead fixing rubber to the

partition plate so that the projection comes to

the refrigerating cycle side.

•

There provided at 2 positions the grooves

to pass the fan motor lead wire into the

motor base. Use the lower groove.

CAUTION

Using the metal band of the motor base, be sure

to fix the fan motor lead to the motor base so that

the fan motor lead does not come to contact with

the propeller fan.

Remarks

FILE NO. SVM-18052

- 100 -