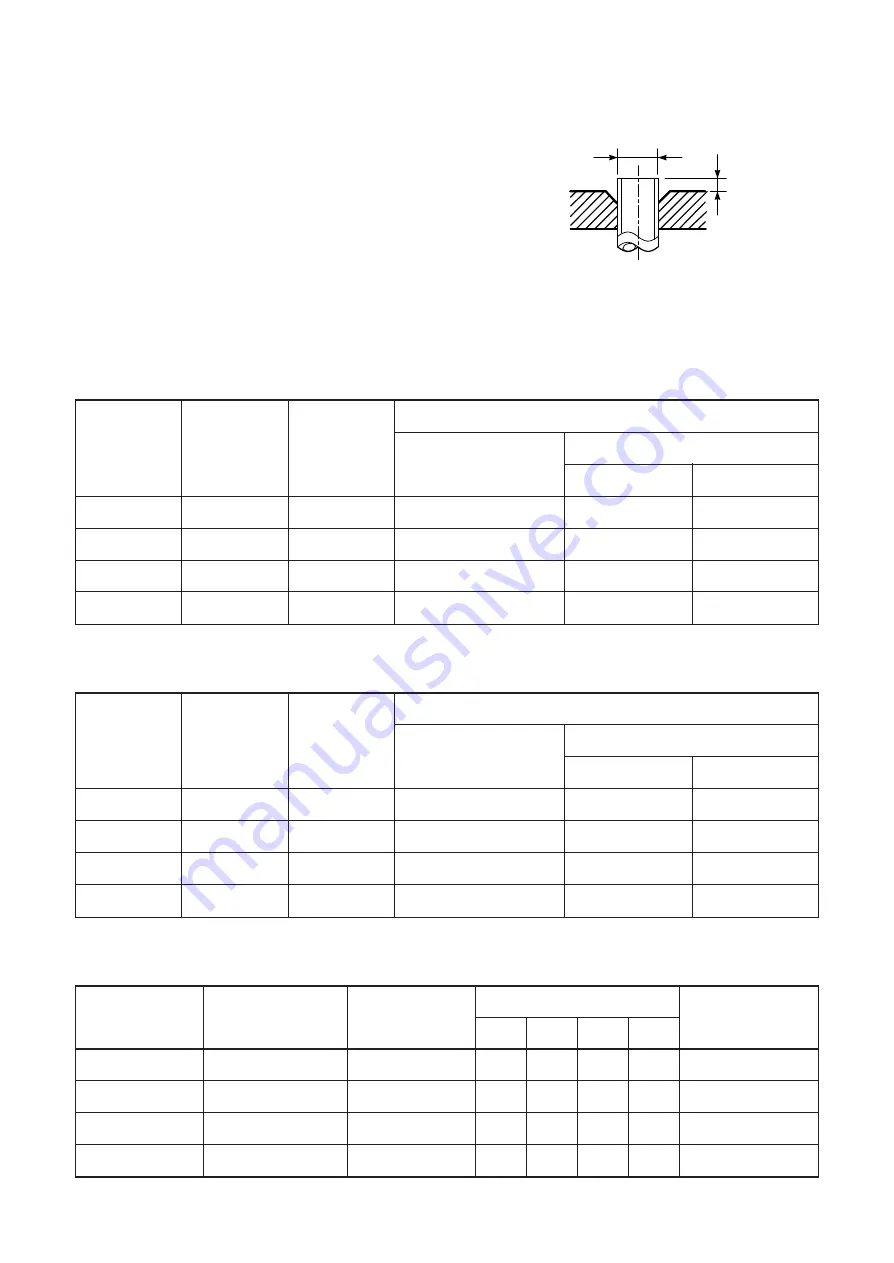

A

ØD

d) Flare Processing

Make certain that a clamp bar and copper

pipe have been cleaned.

By means of the clamp bar, perform the flare

processing correctly.

Use either a flare tool for R410A or conven-

tional flare tool.

Flare processing dimensions differ according

to the type of flare tool.

When using a conventional flare tool, be sure

to secure “dimension A” by using a gauge for

size adjustment.

Fig. 3-2-1 Flare processing dimensions

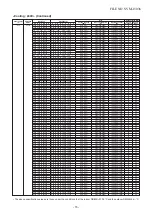

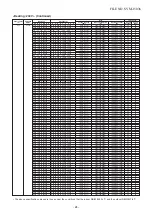

Table 3-2-3 Dimensions related to flare processing for R410A

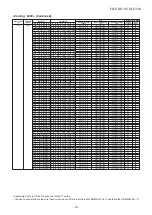

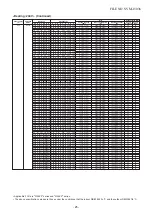

Table 3-2-4 Dimensions related to flare processing for R22

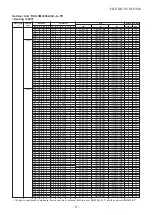

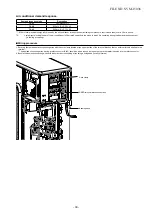

Table 3-2-5 Flare and flare nut dimensions for R410A

Nominal

diameter

1/4

3/8

1/2

5/8

Outer

diameter

(mm)

6.35

9.52

12.70

15.88

Thickness

(mm)

0.8

0.8

0.8

1.0

A (mm)

Flare tool for R410A

Conventional flare tool

clutch type

Clutch type

Wing nut type

0 to 0.5

1.0 to 1.5

1.5 to 2.0

0 to 0.5

1.0 to 1.5

1.5 to 2.0

0 to 0.5

1.0 to 1.5

2.0 to 2.5

0 to 0.5

1.0 to 1.5

2.0 to 2.5

Nominal

diameter

1/4

3/8

1/2

5/8

Outer

diameter

(mm)

6.35

9.52

12.70

15.88

Thickness

(mm)

0.8

0.8

0.8

1.0

A (mm)

Flare tool for R22

Conventional flare tool

clutch type

Clutch type

Wing nut type

0 to 0.5

0.5 to 1.0

1.0 to 1.5

0 to 0.5

0.5 to 1.0

1.0 to 1.5

0 to 0.5

0.5 to 1.0

1.5 to 2.0

0 to 0.5

0.5 to 1.0

1.5 to 2.0

Nominal

diameter

1/4

3/8

1/2

5/8

Outer diameter

(mm)

6.35

9.52

12.70

15.88

Thickness

(mm)

0.8

0.8

0.8

1.0

Dimension (mm)

A

B

C

D

9.1

9.2

6.5

13

13.2

13.5

9.7

20

16.0

16.6

12.9

23

19.0

19.7

16.0

25

Flare nut width

(mm)

17

22

26

29

FILE NO. SVM-15036

- 29 -

Summary of Contents for RAS-5M34S3AV-A

Page 112: ......