1. SAFETY PRECAUTIONS

The important contents concerned to the safety are described on the product itself and on this Service Manual.

Please read this Service Manual after understanding the described items thoroughly in the following contents

(Indications/Illustrated marks), and keep them.

[Explanation of indications]

∗

Property damage : Enlarged damage concerned to property, furniture, and domestic animal/pet

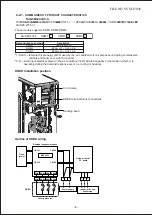

[Explanation of illustrated marks]

For general public use

Power supply cord of outdoor unit shall be more than 2.5 mm² (H07RN-F or 60245IEC66) polychloroprene

sheathed flexible cord.

• Read this “SAFETY PRECAUTIONS” carefully before servicing.

• The precautions described below include the important items regarding safety. Observe them without fail.

• After the servicing work, perform a trial operation to check for any problem.

• Turn off the main power supply switch (or breaker) before the unit maintenance.

CAUTION

New Refrigerant Air Conditioner Installation

• THIS AIR CONDITIONER ADOPTS THE NEW HFC REFRIGERANT (R410A) WHICH DOES NOT

DESTROY OZONE LAYER.

R410A refrigerant is apt to be affected by impurities such as water, oxidizing membrane, and oils because

the working pressure of R410A refrigerant is approx. 1.6 times of refrigerant R22. Accompanied with the

adoption of the new refrigerant, the refrigeration machine oil has also been changed. Therefore, during

installation work, be sure that water, dust, former refrigerant, or refrigeration machine oil does not enter into

the new type refrigerant R410A air conditioner circuit.

To prevent mixing of refrigerant or refrigerating machine oil, the sizes of connecting sections of charging port

on main unit and installation tools are different from those used for the conventional refrigerant units.

Accordingly, special tools are required for the new refrigerant (R410A) units. For connecting pipes, use new

and clean piping materials with high pressure fittings made for R410A only, so that water and/or dust does

not enter. Moreover, do not use the existing piping because there are some problems with pressure fittings

and possible impurities in existing piping.

Indication

DANGER

WARNING

CAUTION

Explanation

Indicates contents assumed that an imminent danger causing a death or serious injury of

the repair engineers and the third parties when an incorrect work has been executed.

Indicates possibilities assumed that a danger causing a death or serious injury of the

repair engineers, the third parties, and the users due to troubles of the product after work

when an incorrect work has been executed.

Indicates contents assumed that an injury or property damage (

∗

) may be caused on the

repair engineers, the third parties, and the users due to troubles of the product after work

when an incorrect work has been executed.

Mark

Explanation

Indicates prohibited items (Forbidden items to do)

The sentences near an illustrated mark describe the concrete prohibited contents.

Indicates mandatory items (Compulsory items to do)

The sentences near an illustrated mark describe the concrete mandatory contents.

Indicates cautions (including danger/warning)

The sentences or illustration near or in an illustrated mark describe the concrete cautious contents.

FILE NO. SVM-15036

- 3 -

Summary of Contents for RAS-5M34S3AV-A

Page 112: ......