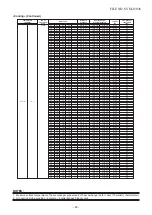

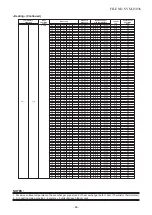

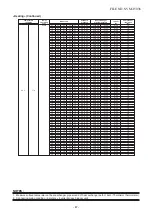

<Cooling> (Continued)

NOTES :

1. Measure surface temperature of heat exchanger pipe around of heat exchanger path U bent. (Thermistor thermometer)

2. Connecting piping condition : 5 meters × 5 units (5m/each indoor unit)

Indoor unit

Indoor

Outdoo

r

A

B

C

D

E

P (MP)

T1 (°C)

T2 (°C)

5 units

07

07

07

07

07

1.0 to 1.2

15 to 17

51 to 53

High

65

10

07

07

07

07

1.0 to 1.2

15 to 17

51 to 53

High

65

13

07

07

07

07

1.0 to 1.2

15 to 17

51 to 53

High

65

16

07

07

07

07

1.0 to 1.2

15 to 17

51 to 53

High

65

18

07

07

07

07

1.0 to 1.2

15 to 17

51 to 53

High

65

10

10

07

07

07

1.0 to 1.2

15 to 17

51 to 53

High

65

13

10

07

07

07

1.0 to 1.2

15 to 17

51 to 53

High

65

16

10

07

07

07

1.0 to 1.2

15 to 17

51 to 53

High

65

18

10

07

07

07

1.0 to 1.2

15 to 17

51 to 53

High

65

13

13

07

07

07

1.0 to 1.2

15 to 17

51 to 53

High

65

16

13

07

07

07

1.0 to 1.2

15 to 17

51 to 53

High

65

18

13

07

07

07

1.0 to 1.2

15 to 17

51 to 53

High

65

16

16

07

07

07

1.0 to 1.2

15 to 17

51 to 53

High

65

18

16

07

07

07

1.0 to 1.2

15 to 17

51 to 53

High

65

10

10

10

07

07

1.0 to 1.2

15 to 17

51 to 53

High

65

13

10

10

07

07

1.0 to 1.2

15 to 17

51 to 53

High

65

13

13

10

07

07

1.0 to 1.2

15 to 17

51 to 53

High

65

16

10

10

07

07

1.0 to 1.2

15 to 17

51 to 53

High

65

18

10

10

07

07

1.0 to 1.2

15 to 17

51 to 53

High

65

13

13

13

07

07

1.0 to 1.2

15 to 17

51 to 53

High

65

16

13

13

07

07

1.0 to 1.2

15 to 17

51 to 53

High

65

18

13

13

07

07

1.0 to 1.2

15 to 17

51 to 53

High

65

16

16

10

07

07

1.0 to 1.2

15 to 17

51 to 53

High

65

18

16

10

07

07

1.0 to 1.2

15 to 17

51 to 53

High

65

18

13

13

07

07

1.0 to 1.2

15 to 17

51 to 53

High

65

16

16

13

07

07

1.0 to 1.2

15 to 17

51 to 53

High

65

18

16

13

07

07

1.0 to 1.2

15 to 17

51 to 53

High

65

10

10

10

10

07

1.0 to 1.2

15 to 17

51 to 53

High

65

13

10

10

10

07

1.0 to 1.2

15 to 17

51 to 53

High

65

16

10

10

10

07

1.0 to 1.2

15 to 17

51 to 53

High

65

18

10

10

10

07

1.0 to 1.2

15 to 17

51 to 53

High

65

13

13

10

10

07

1.0 to 1.2

15 to 17

51 to 53

High

65

16

13

10

10

07

1.0 to 1.2

15 to 17

51 to 53

High

65

18

13

10

10

07

1.0 to 1.2

15 to 17

51 to 53

High

65

16

16

10

10

07

1.0 to 1.2

15 to 17

51 to 53

High

65

13

13

13

10

07

1.0 to 1.2

15 to 17

51 to 53

High

65

16

13

13

10

07

1.0 to 1.2

15 to 17

51 to 53

High

65

13

13

13

13

07

1.0 to 1.2

15 to 17

51 to 53

High

65

16

13

13

13

07

1.0 to 1.2

15 to 17

51 to 53

High

65

16

16

13

13

07

1.0 to 1.2

15 to 17

51 to 53

High

65

27 / 19

35 / –

10

10

10

10

10

1.0 to 1.2

15 to 17

51 to 53

High

65

13

10

10

10

10

1.0 to 1.2

15 to 17

51 to 53

High

65

16

10

10

10

10

1.0 to 1.2

15 to 17

51 to 53

High

65

18

10

10

10

10

1.0 to 1.2

15 to 17

51 to 53

High

65

13

13

10

10

10

1.0 to 1.2

15 to 17

51 to 53

High

65

16

13

10

10

10

1.0 to 1.2

15 to 17

51 to 53

High

65

18

13

10

10

10

1.0 to 1.2

15 to 17

51 to 53

High

65

16

16

10

10

10

1.0 to 1.2

15 to 17

51 to 53

High

65

13

13

13

10

10

1.0 to 1.2

15 to 17

51 to 53

High

65

16

13

13

10

10

1.0 to 1.2

15 to 17

51 to 53

High

65

18

13

13

10

10

1.0 to 1.2

15 to 17

51 to 53

High

65

16

16

13

10

10

1.0 to 1.2

15 to 17

51 to 53

High

65

13

13

13

13

10

1.0 to 1.2

15 to 17

51 to 53

High

65

16

13

13

13

10

1.0 to 1.2

15 to 17

51 to 53

High

65

18

13

13

13

10

1.0 to 1.2

15 to 17

51 to 53

High

65

16

16

13

13

10

1.0 to 1.2

15 to 17

51 to 53

High

65

13

13

13

13

13

1.0 to 1.2

15 to 17

51 to 53

High

65

16

13

13

13

13

1.0 to 1.2

15 to 17

51 to 53

High

65

22

07

07

07

07

1.0 to 1.2

15 to 17

51 to 53

High

65

22

10

07

07

07

1.0 to 1.2

15 to 17

51 to 53

High

65

22

10

10

07

07

1.0 to 1.2

15 to 17

51 to 53

High

65

22

10

10

10

07

1.0 to 1.2

15 to 17

51 to 53

High

65

22

10

10

10

10

1.0 to 1.2

15 to 17

51 to 53

High

65

22

13

07

07

07

1.0 to 1.2

15 to 17

51 to 53

High

65

22

13

10

07

07

1.0 to 1.2

15 to 17

51 to 53

High

65

22

13

10

10

07

1.0 to 1.2

15 to 17

51 to 53

High

65

22

13

10

10

10

1.0 to 1.2

15 to 17

51 to 53

High

65

22

13

13

07

07

1.0 to 1.2

15 to 17

51 to 53

High

65

22

13

13

10

07

1.0 to 1.2

15 to 17

51 to 53

High

65

22

13

13

10

10

1.0 to 1.2

15 to 17

51 to 53

High

65

22

13

13

13

07

1.0 to 1.2

15 to 17

51 to 53

High

65

24

07

07

07

07

1.0 to 1.2

15 to 17

51 to 53

High

65

24

10

07

07

07

1.0 to 1.2

15 to 17

51 to 53

High

65

24

10

10

07

07

1.0 to 1.2

15 to 17

51 to 53

High

65

24

10

10

10

07

1.0 to 1.2

15 to 17

51 to 53

High

65

24

10

10

10

10

1.0 to 1.2

15 to 17

51 to 53

High

65

24

13

07

07

07

1.0 to 1.2

15 to 17

51 to 53

High

65

24

13

10

07

07

1.0 to 1.2

15 to 17

51 to 53

High

65

24

13

10

10

07

1.0 to 1.2

15 to 17

51 to 53

High

65

24

13

10

10

10

1.0 to 1.2

15 to 17

51 to 53

High

65

24

13

13

07

07

1.0 to 1.2

15 to 17

51 to 53

High

65

24

13

13

10

07

1.0 to 1.2

15 to 17

51 to 53

High

65

Temperature

condition

No. of

operating

units

Heat exchanger

pipe temperature

Standard

pressure

Indoor

fan

Compressor

revolution

(rps)

FILE NO. SVM-15036

- 44 -

Summary of Contents for RAS-5M34S3AV-A

Page 112: ......