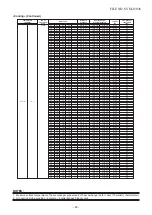

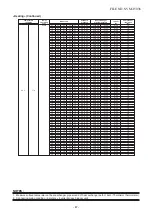

<Heating> (Continued)

NOTES :

1. Measure surface temperature of heat exchanger pipe around of heat exchanger path U bent. (Thermistor thermometer)

2. Connecting piping condition : 5 meters × 5 units (5m/each indoor unit)

Indoor unit

Indoor

Outdoor

A

B

C

D

E

P (MP)

T1 (°C)

T2 (°C)

4 units

07

07

07

07

—

2.5 to 2.7

35 to 37

–2 to 0

High

60

10

07

07

07

—

2.5 to 2.7

35 to 37

–2 to 0

High

60

13

07

07

07

—

2.5 to 2.7

35 to 37

–2 to 0

High

60

16

07

07

07

—

2.5 to 2.7

35 to 37

–2 to 0

High

60

18

07

07

07

—

2.5 to 2.7

35 to 37

–2 to 0

High

60

22

07

07

07

—

2.5 to 2.7

35 to 37

–2 to 0

High

60

24

07

07

07

—

2.5 to 2.7

35 to 37

–2 to 0

High

60

10

10

07

07

—

2.5 to 2.7

35 to 37

–2 to 0

High

60

13

10

07

07

—

2.5 to 2.7

35 to 37

–2 to 0

High

60

16

10

07

07

—

2.5 to 2.7

35 to 37

–2 to 0

High

60

18

10

07

07

—

2.5 to 2.7

35 to 37

–2 to 0

High

60

22

10

07

07

—

2.5 to 2.7

35 to 37

–2 to 0

High

60

24

10

07

07

—

2.5 to 2.7

35 to 37

–2 to 0

High

60

13

13

07

07

—

2.5 to 2.7

35 to 37

–2 to 0

High

60

16

13

07

07

—

2.5 to 2.7

35 to 37

–2 to 0

High

60

18

13

07

07

—

2.5 to 2.7

35 to 37

–2 to 0

High

60

22

13

07

07

—

2.4 to 2.6

34 to 36

–2 to 0

High

60

24

13

07

07

—

2.2 to 2.4

33 to 35

–2 to 0

High

60

16

16

07

07

—

2.5 to 2.7

35 to 37

–2 to 0

High

60

18

16

07

07

—

2.4 to 2.6

34 to 36

–2 to 0

High

60

22

16

07

07

—

2.2 to 2.4

33 to 35

–2 to 0

High

60

24

16

07

07

—

2.2 to 2.4

33 to 35

–2 to 0

High

60

18

18

07

07

—

2.2 to 2.4

33 to 35

–2 to 0

High

60

22

18

07

07

—

2.2 to 2.4

33 to 35

–2 to 0

High

60

24

18

07

07

—

2.2 to 2.4

33 to 35

–2 to 0

High

60

10

10

10

07

—

2.5 to 2.7

35 to 37

–2 to 0

High

60

13

10

10

07

—

2.5 to 2.7

35 to 37

–2 to 0

High

60

16

10

10

07

—

2.5 to 2.7

35 to 37

–2 to 0

High

60

18

10

10

07

—

2.5 to 2.7

35 to 37

–2 to 0

High

60

22

10

10

07

—

2.5 to 2.7

35 to 37

–2 to 0

High

60

24

10

10

07

—

2.4 to 2.6

34 to 36

–2 to 0

High

60

13

13

10

07

—

2.5 to 2.7

35 to 37

–2 to 0

High

60

16

13

10

07

—

2.5 to 2.7

35 to 37

–2 to 0

High

60

18

13

10

07

—

2.5 to 2.7

35 to 37

–2 to 0

High

60

22

13

10

07

—

2.2 to 2.4

33 to 35

–2 to 0

High

60

24

13

10

07

—

2.2 to 2.4

33 to 35

–2 to 0

High

60

16

16

10

07

—

2.4 to 2.6

34 to 36

–2 to 0

High

60

18

16

10

07

—

2.2 to 2.4

33 to 35

–2 to 0

High

60

22

16

10

07

—

2.2 to 2.4

33 to 35

–2 to 0

High

60

24

16

10

07

—

2.2 to 2.4

33 to 35

–2 to 0

High

60

18

18

10

07

—

2.2 to 2.4

33 to 35

–2 to 0

High

60

22

18

10

07

—

2.2 to 2.4

33 to 35

–2 to 0

High

60

24

18

10

07

—

2.2 to 2.4

33 to 35

–2 to 0

High

60

13

13

13

07

—

2.4 to 2.6

34 to 36

–2 to 0

High

60

16

13

13

07

—

2.2 to 2.4

33 to 35

–2 to 0

High

60

18

13

13

07

—

2.2 to 2.4

33 to 35

–2 to 0

High

60

22

13

13

07

—

2.2 to 2.4

33 to 35

–2 to 0

High

60

20 / –

7 / 6

24

13

13

07

—

2.2 to 2.4

33 to 35

–2 to 0

High

60

16

16

13

07

—

2.2 to 2.4

33 to 35

–2 to 0

High

60

18

16

13

07

—

2.2 to 2.4

33 to 35

–2 to 0

High

60

22

16

13

07

—

2.2 to 2.4

33 to 35

–2 to 0

High

60

24

16

13

07

—

2.2 to 2.4

33 to 35

–2 to 0

High

60

18

18

13

07

—

2.2 to 2.4

33 to 35

–2 to 0

High

60

22

18

13

07

—

2.2 to 2.4

33 to 35

–2 to 0

High

60

24

18

13

07

—

2.2 to 2.4

33 to 35

–2 to 0

High

60

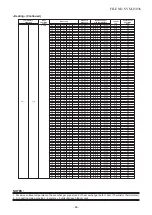

10

10

10

10

—

2.5 to 2.7

35 to 37

–2 to 0

High

60

13

10

10

10

—

2.5 to 2.7

35 to 37

–2 to 0

High

60

16

10

10

10

—

2.5 to 2.7

35 to 37

–2 to 0

High

60

18

10

10

10

—

2.5 to 2.7

35 to 37

–2 to 0

High

60

22

10

10

10

—

2.4 to 2.6

34 to 36

–2 to 0

High

60

24

10

10

10

—

2.4 to 2.6

34 to 36

–2 to 0

High

60

13

13

10

10

—

2.5 to 2.7

35 to 37

–2 to 0

High

60

16

13

10

10

—

2.4 to 2.6

34 to 36

–2 to 0

High

60

22

13

10

10

—

2.2 to 2.4

33 to 35

–2 to 0

High

60

24

13

10

10

—

2.2 to 2.4

33 to 35

–2 to 0

High

60

16

16

10

10

—

2.4 to 2.6

34 to 36

–2 to 0

High

60

18

13

10

10

—

2.4 to 2.6

34 to 36

–2 to 0

High

60

22

16

10

10

—

2.2 to 2.4

33 to 35

–2 to 0

High

60

24

16

10

10

—

2.4 to 2.6

34 to 36

–2 to 0

High

60

18

16

10

10

—

2.4 to 2.6

34 to 36

–2 to 0

High

60

18

18

10

10

—

2.2 to 2.4

33 to 35

–2 to 0

High

60

22

18

10

10

—

2.4 to 2.6

34 to 36

–2 to 0

High

60

24

18

10

10

—

2.4 to 2.6

34 to 36

–2 to 0

High

60

13

13

13

10

—

2.2 to 2.4

33 to 35

–2 to 0

High

60

16

13

13

10

—

2.2 to 2.4

33 to 35

–2 to 0

High

60

18

13

13

10

—

2.2 to 2.4

33 to 35

–2 to 0

High

60

22

13

13

10

—

2.4 to 2.6

34 to 36

–2 to 0

High

60

24

13

13

10

—

2.4 to 2.6

34 to 36

–2 to 0

High

60

18

16

13

10

—

2.2 to 2.4

33 to 35

–2 to 0

High

60

22

16

13

10

—

2.4 to 2.6

34 to 36

–2 to 0

High

60

24

16

13

10

—

2.4 to 2.6

34 to 36

–2 to 0

High

60

18

18

13

10

—

2.2 to 2.4

33 to 35

–2 to 0

High

60

22

18

13

10

—

2.4 to 2.6

34 to 36

–2 to 0

High

60

24

18

13

10

—

2.4 to 2.6

34 to 36

–2 to 0

High

60

13

13

13

13

—

2.2 to 2.4

33 to 35

–2 to 0

High

60

16

13

13

13

—

2.2 to 2.4

33 to 35

–2 to 0

High

60

18

13

13

13

—

2.2 to 2.4

33 to 35

–2 to 0

High

60

22

13

13

13

—

2.4 to 2.6

34 to 36

–2 to 0

High

60

24

13

13

13

—

2.4 to 2.6

34 to 36

–2 to 0

High

60

16

16

13

13

—

2.2 to 2.4

33 to 35

–2 to 0

High

60

18

16

13

13

—

2.2 to 2.4

33 to 35

–2 to 0

High

60

22

16

13

13

—

2.4 to 2.6

34 to 36

–2 to 0

High

60

24

16

13

13

—

2.4 to 2.6

34 to 36

–2 to 0

High

60

18

18

13

13

—

2.2 to 2.4

33 to 35

–2 to 0

High

60

22

18

13

13

—

2.4 to 2.6

34 to 36

–2 to 0

High

60

24

18

13

13

—

2.4 to 2.6

34 to 36

–2 to 0

High

60

Temperature

condition

No. of

operating

units

Compressor

revolution

(rps)

Standard

pressure

Heat exchanger

pipe temperature

Indoor

fan

FILE NO. SVM-15036

- 46 -

Summary of Contents for RAS-5M34S3AV-A

Page 112: ......