–

22

–

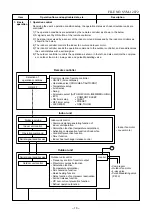

Item

7. Temporary

operation

Operation flow and applicable data, etc.

Pressing [RESET] button starts the temporary opera-

tion of [AUTO] operation. When keeping [RESET]

button pressed for 10 seconds or more, the temporary

[COOL] operation is performed.

Description

1) When pressing [RESET] button, the

temporary [AUTO] operation starts.

2) When keeping [RESET] button pressed

for 3 seconds or more, Pi, Pi, Pi sound is

heard and [AUTO RESTART] control is

changed.

3) When keeping [RESET] button pressed

for 10 seconds or more, “Pi” sound is

heard and the temporary [COOL]

operation starts.

4) If the filter lamp goes on, press [RESET]

button to go off the filter lamp, and then

press [RESET] button again.

5) To stop the temporary operation, press

the button again.

Filter lamp ON

Press RESET button.

Did you press [RESET] button

for 3 seconds or more?

Did you press [RESET] button

for 10 seconds or more?

Switch to [AUTO RESTART] control.

YES

YES

NO

NO

NO

YES

Temporary [AUTO] operation

Temporary [COOL] Operation

FILE NO. SVM-12072