– 80 –

No.

Part name

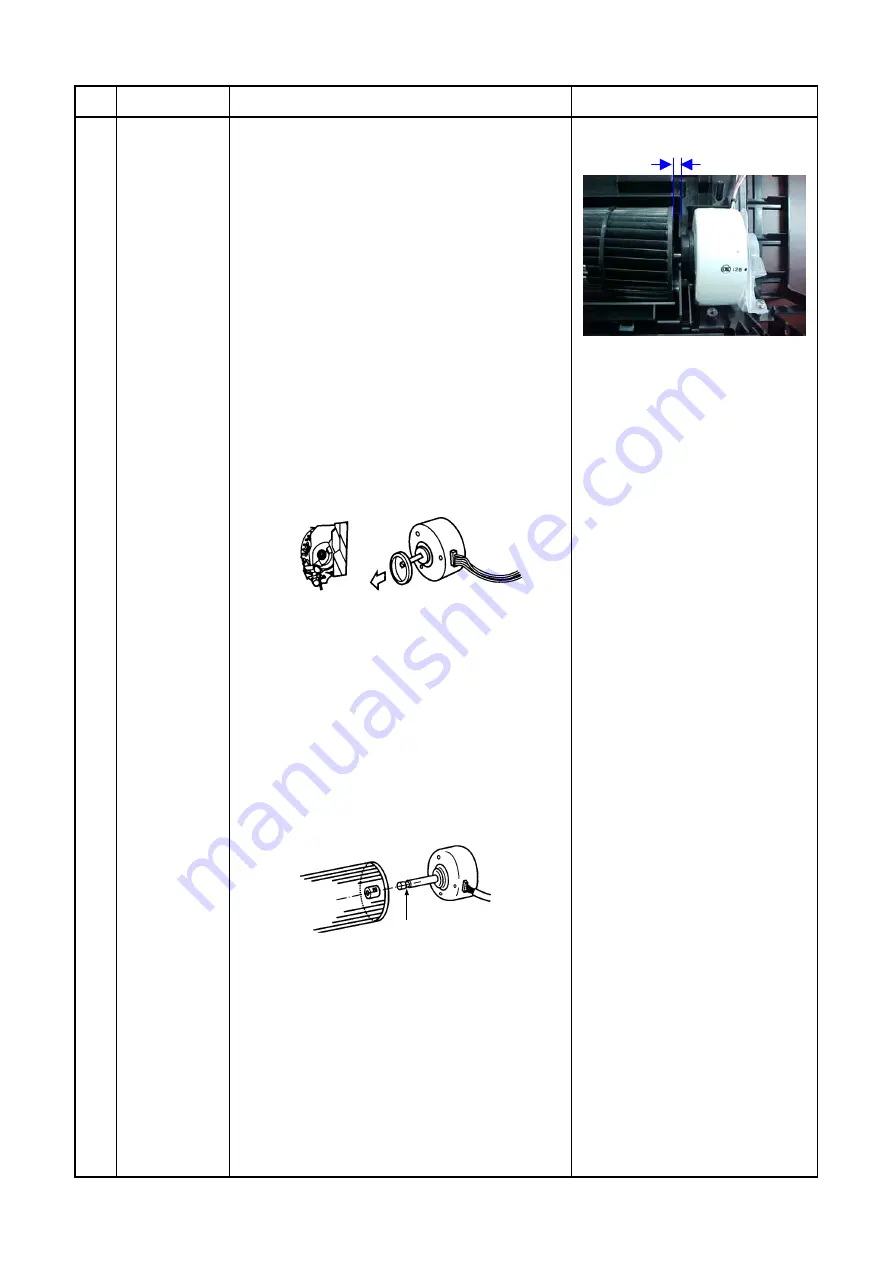

Cross flow fan

Procedures

<Caution at reassembling>

1) To incorporate the fan motor, remove the fan

motor rubber (at shaft core side), incorporate

the motor into the position in the following

figure, and then install the fan motor.

Remarks

U groove

• Install the cross flow fan so that the right

end of the 1st joint from the right of the

cross flow fan is set keeping 70.5 mm from

wall of rear plate of the main unit.

• Holding the set screw, install the cross flow

fan so that U-groove of the fan motor comes

to the mounting hole of the set screw.

• Perform positioning of the fan motor as

follows:

• When assembling the fan motor, the fan

motor must be installed in such a way that

the fan motor leads will be taken out is

positioned at the bottom front.

• After assembling the two hooking claws of

the motor band (right) into the main body,

position the fan motor, insert it, and then

secure the motor band (right) using the two

fixing screws.

5 mm

p