2) Changing of air flow (Fan setting : AUTO)

When the Hi POWER is started, the fan of the

indoor unit operates at higher air flow level than

normal air flow AUTO (normal air flow AUTO

is shown in Fig. 6-2-2). Because of the

FILE NO. SVM-05019

6-2-3. DRY Operation

(The Remote controller [MODE] Button

is Set to the DRY Position)

•

Once the setting is made, the operation mode is

memorized in the microcomputer so that the same

operation can be effected thereafter simply by

pushing [ ] button.

•

Dry operation signal is transmitted to outdoor unit.

•

The Cooling operation giving priority to dehumidi-

fying, which restrains the indoor fan speed and

compressor motor speed, is performed.

•

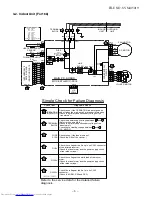

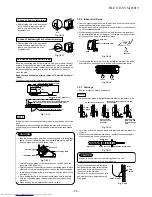

The indoor fan motor operates as shown in Fig.

6

-2-7. (Fan speed is AUTO only.)

•

The outdoor unit controls the outdoor fan relay

R01, R02 and R03, and the compressor motor

speed according to the operation command signal

sent from the indoor unit.

–0.5

0

+0.5

+1.0

+1.5

+2.0

+2.5

*1

L–

SUL

(Room temp

.)

–

(Set temp

.)

Set

temp.

NOTE :

*

1 : Middle motor speed between L– and SUL

Fig. 6-2-7 Setting of air flow

difference between room temperature and set

temperature are increased automatically.

3) Changing of air flow (Fan setting : One of 5

levels)

When the Hi POWER is started, the fan of the

indoor unit operates at higher consecutive air

flow level. (Fan speed on the display of remote

control does not change)

4) Changing of louver position

If the room temperature is higher than setting

temperature by 3.5 °C or more, the louver is

automatically set to the maximum air flow

position. If it is not, position of louver is not

change. When room temperature is reach to

setting temperature. The louver moves back

to set position.

(11) Quiet operation control.

When the [QUIET] button is pushed, the fan is

restricted the revolution speed at L- level until

the [QUIET] button is pushed once again

(cancel QUIET operation).

Remarks :

QUIET operation is appropriate to work with

less cooling load condition. Because of the

fan speed L- may cause not enough the

cooling capacity.

(1) Dehumidifying-preferential Cooling capacity

control

•

The cooling capacity and room temperature are

controlled by changing the compressor motor

speed according to both the difference between

the temperature detected by the room temperature

sensor and the temperature set by [TEMP] button

and also any change in room temperature.

•

When the air conditioner operates in Dry mode, the

maximum compressor motor speed is restricted.

M10 : Max. 20 rps

M13 : Max. 20 rps

M16 : Max. 22 rps

While multiple indoor units operate, compressor

motor speed is calculated in the outdoor unit to

operate.

•

When room temperature is lower than set tempera-

ture, indoor fan motor is operated at fan speed SUL

as shown in Fig.

6

-2-6 while the outdoor unit stops.

•

ECONO Hi POWER, QUIET and COMFORT-

SLEEP mode cannot be set.

−

15

−

•

Other controls than the above-mentioned controls

are common to those of cooling operation.