– 88 –

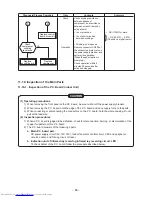

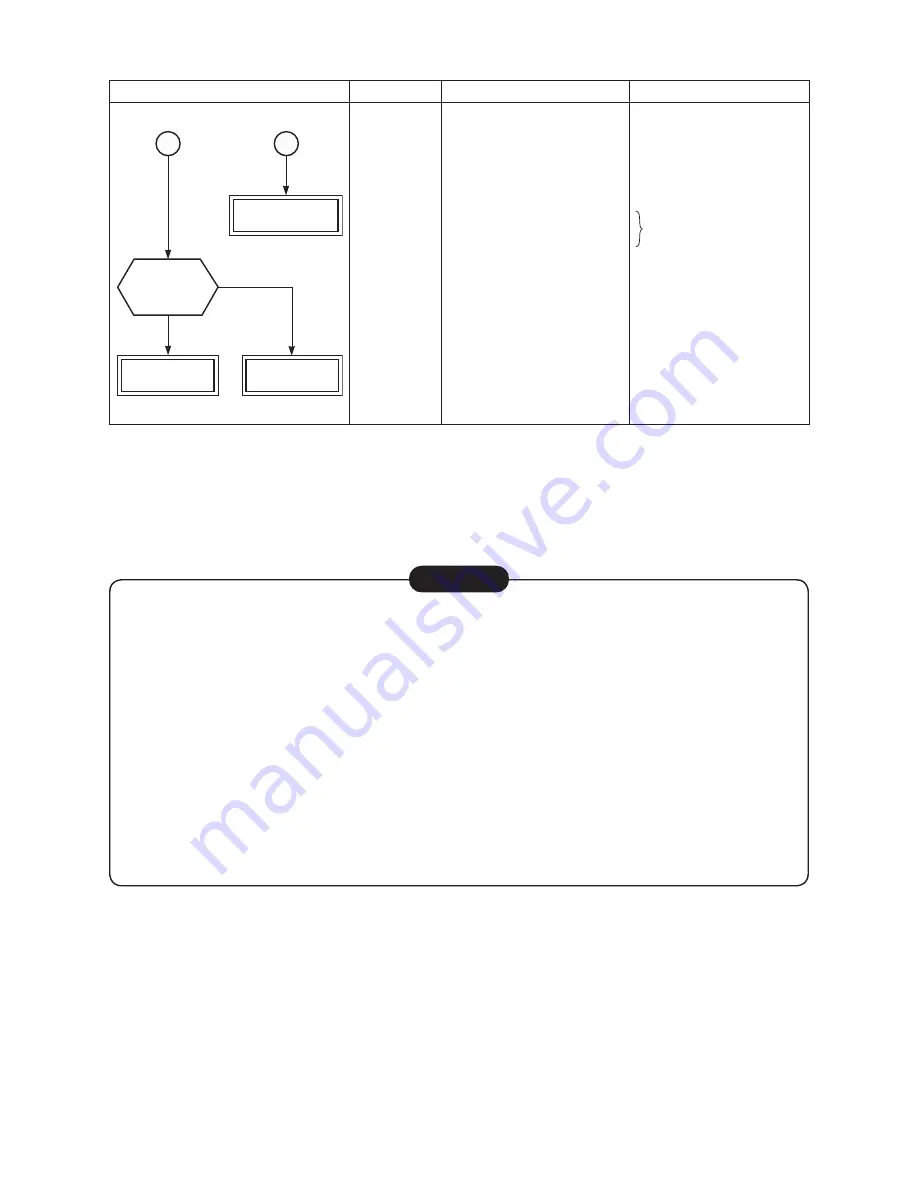

Diagnosis/Process

fl

owchart

Item

Contents

Summary

NG

OK

B

A

Replace control

board assembly.

Replace

control board.

Replace

compressor.

Check

compressor

winding

resistance.

Check

Check winding resistance

between phases of

compressor, and resistance

between outdoor frames by

using a tester.

Is not grounded.

•

→

OK if 10M

Ω

or more

Is not short-circuited

between windings.

•

→

OK if 0.51

Ω

→

0.57

Ω

(Check by a digital tester.)

Winding is not opened.

•

Operation

Remove connector CN300 of

the outdoor fan motor, turn on

the power supply breaker, and

perform the operation.

(Stops though activation is

prompted.)

Check operation within 2

minutes 20 seconds after

activation stopped.

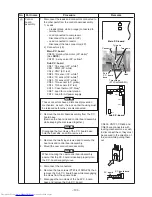

11-10. Inspection of the Main Parts

11-10-1. Inspection of the P.C. Board (Indoor Unit)

(1) Operating precautions

1) When removing the front panel or the P.C. board, be sure to shut off the power supply breaker.

2) When removing the P.C. board, hold the edge of the P.C. board and do not apply force to the parts.

3) When connecting or disconnecting the connectors on the P.C. board, hold the whole housing. Do not

pull at the lead wire.

(2) Inspection procedures

1) When a P.C. board is judged to be defective, check for disconnection, burning, or discoloration of the

copper foil pattern or this P.C. board.

2) The P.C. board consists of the following 2 parts

a. Main P.C. board part :

DC power supply circuit (5V, 12V, 35V), Indoor fan motor control circuit, CPU and peripheral

circuits, buzzer, and Driving circuit of louver.

b. Indication unit of infrared ray receiving infrared ray receiving circuit, LED :

To check defect of the P.C. board, follow the procedure described below.

CAUTION