– 28 –

25mm or more

Duct board

Weight of thermal

insulator (glass wool) is

64 kg/m³ or equivalent.

25mm or more

Ø150mm or more

Weight of thermal

insulator (glass wool) is

24 kg/m³ or equivalent.

A

B

( )

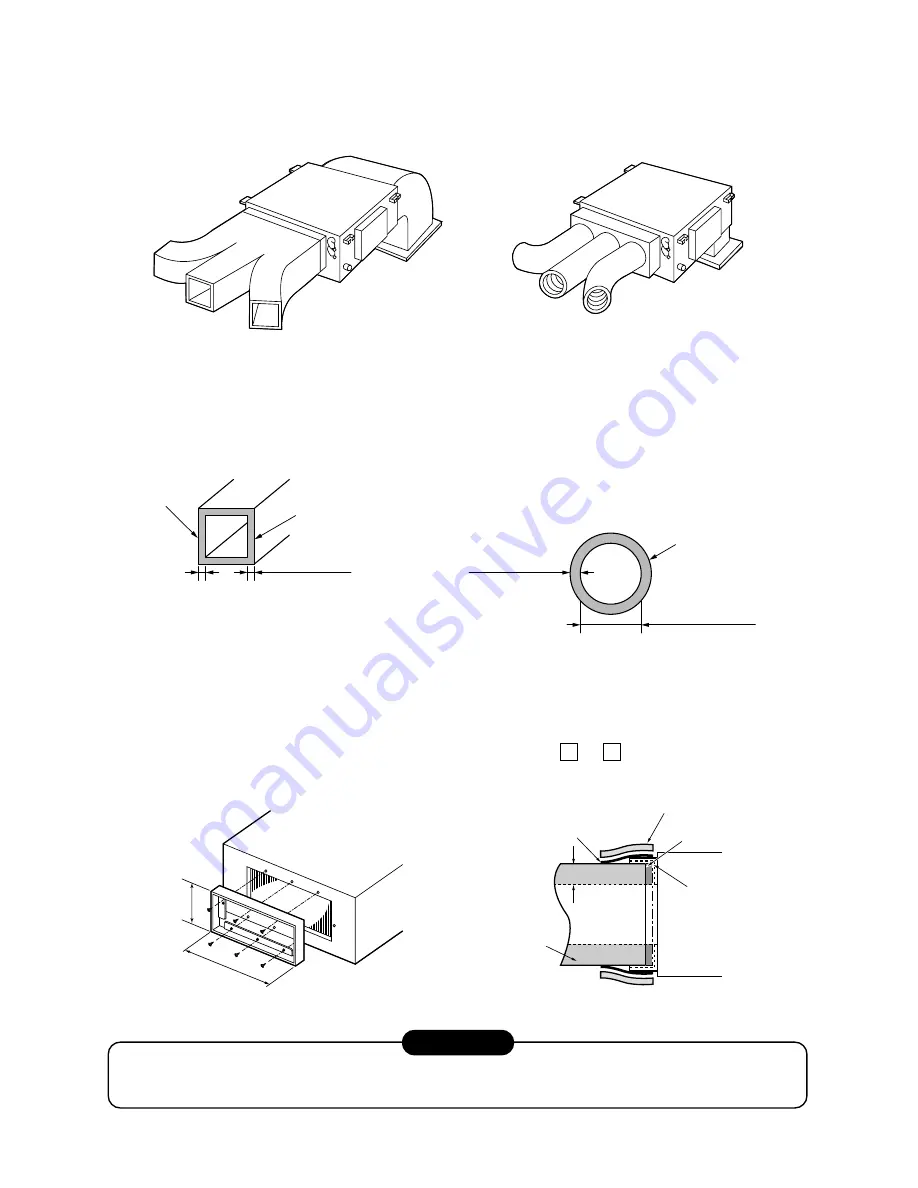

Thermal insulator (50mm (w), 6mm (t))

Seal

Thermal insulator :

25mm (w), 6mm (t)

Aluminum tape

(50mm-width)

Square

duct board

(25mm)

25mm

End

Indoor unit

9-4-2. Installation Reference

The air supply ducting work is classified into two ways, one is branched by the square ducts, and the other is

branched by the round ducts. (Be sure to divide the air supply duct into three or more branches.)

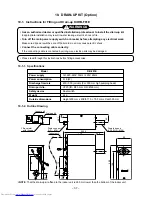

[Square duct]

Fig. 9-4-4

In case of using the square duct, apply the thermal

insulator of thickness by 25mm or more to the duct

board. For the thermal insulator, use high-density

glass wool of weight by 64kg/m

3

.

Fig. 9-4-6

[Round duct]

Fig. 9-4-5

In case of using the round duct, use the thermal

insulator of thickness by 25mm or more and inner

diameter by 150mm or more to the duct board. (If the

inner diameter is not enough, resistance generates,

as the result, air does not flow smoothly and loss of

the static pressure increases.) For the thermal

insulator, use high-density glass wool of weight by

24kg/m

3

or equivalent.

Fig. 9-4-7

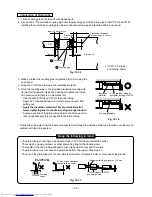

9-4-3. Connecting Method of the Duct

1. Supply air side

1) Using 6 screws, mount the flange to the supply air port of the indoor unit. (Fig. 9-4-8)

2) Make the square duct according to inner dimension of the flange. A x B .

Use a glass wool board with inside/outside finishing by 25mm-thickness and 64kg/m³-density.

3) Connect the flange and each type of duct. (Fig. 9-4-9)

Fig. 9-4-8

Fig. 9-4-9

CAUTION

Incomplete thermal insulation of the supply air flange and sealing may occur dewing resulted in falling of

water drop.

Summary of Contents for RAS-M10YDCV-E

Page 62: ......