– 46 –

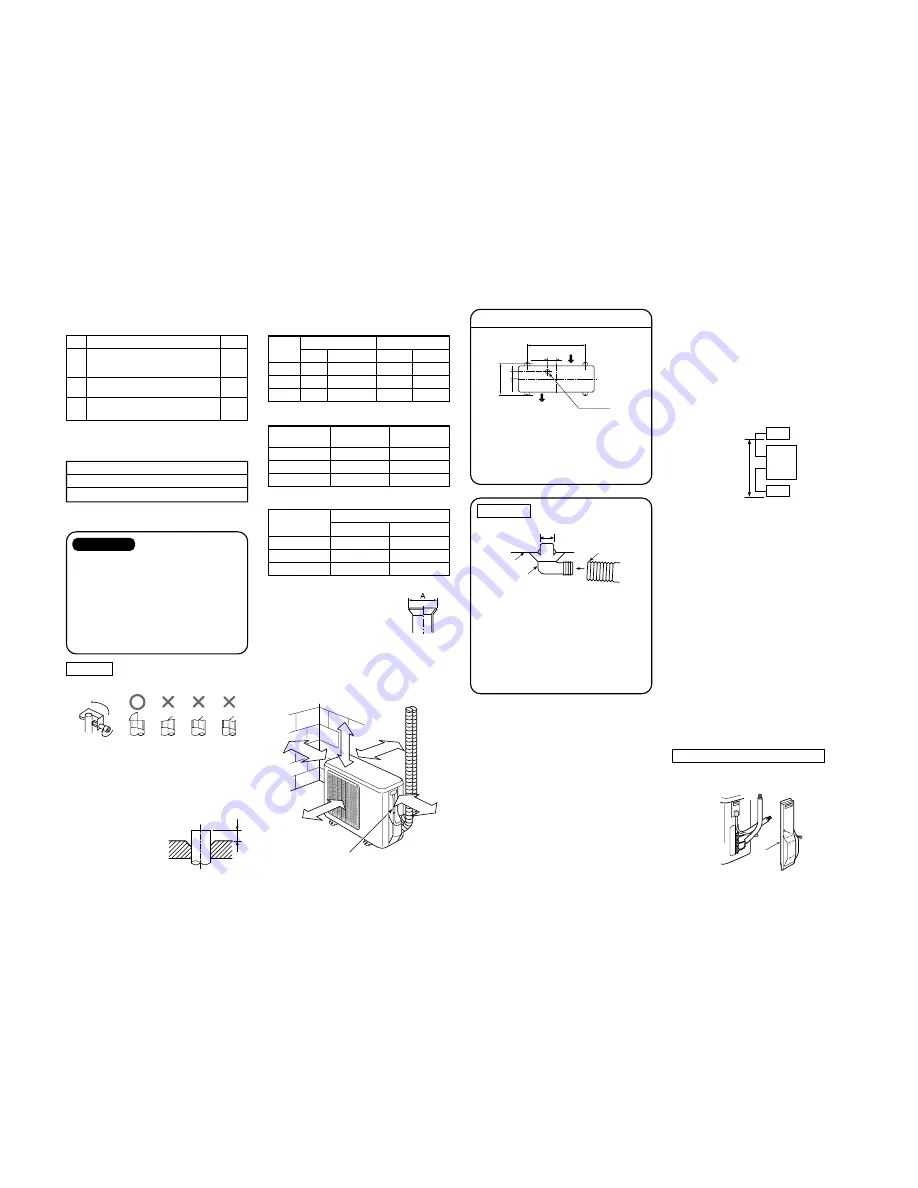

9-3-4. Optional Installation Parts

(Local Supply)

A

B

C

Parts name

Refrigerant piping

Liquid side : ø6,35 mm

Gas side : ø9,52 mm or ø12,7 mm

Pipe insulating material

(polyethylene foam, 6 mm thick)

Putty, PVC tapes

Q’ty

Each

one

1

Each

one

9-3-5. Optional Installation Parts

(Separate Sold)

Parts name

RB-M43RE

Reducer

(Ø12,7

→

Ø9,52)

RB-M34EE

Expander (Ø9,52

→

Ø12,7)

600

115

Suction side

Diffuser

310

76

Drain hole

9-3-6. Refrigerant Piping Connection

CAUTION

KEEP IMPORTANT 4 POINTS FOR PIPING

WORK

1. Take away dust and moisture.

(Inside of the connecting pipes)

2. Tight connection (between pipes and unit)

3. Evacuate the air in the connecting pipes

using VACUUM PUMP.

4. Check gas leak. (connected points)

Flaring

1. Cut the pipe with a pipe cutter.

Fig. 9-3-3

Drain hose sold

separately or one

on the market.

Drain nipple

Bottom plate

ø25

90˚

Obliquity

Roughness

Warp

B

+ 0

– 0,4

As shown in the figure, hang power cord

and connecting cable downward, and

take out it along piping connection port.

250mm or

more from w

all

200mm or more

600mm or more

50mm or more

from w

all

100mm or

more from w

all

Fig. 9-3-2

2. Insert a flare nut into the pipe, and flare the

pipe.

As the flaring sizes of R410A differ from those

of refrigerant R22, the flare tools newly

manufactured for R410A are recommended.

However, the

conventional tools can

be used by adjusting

projection margin of

the copper pipe.

• Projection margin in flaring : B (Unit : mm)

Rigid (Clutch type)

Outer dia.

of copper

pipe

6,35

9,52

12,7

R410A tool used

R410A

R22

0

~

0,5 (Same as left)

0

~

0,5 (Same as left)

0

~

0,5 (Same as left)

Conventional tool used

R410A

R22

1,0

~

1,5

0,5

~

1,0

1,0

~

1,5

0,5

~

1,0

1,0

~

1,5

0,5

~

1,0

Imperial (Wing nut type)

Outer dia. of

R410A

R22

copper pipe

6,35

1,5

~

2,0

1,0

~

1,5

9,52

1,5

~

2,0

1,0

~

1,5

12,7

2,0

~

2,5

1,5

~

2,0

• Flaring size : A (Unit : mm)

Outer dia. of

A

copper pipe

R410A

R22

6,35

9,1

9,0

9,52

13,2

13,0

12,7

16,6

16,2

*

In the case of flaring for R410A

with the conventional flare tool,

pull out it approx. 0,5 mm more

than that for R22 to adjust to the

specified flare size.

The copper pipe gauge is

useful for adjusting projection

margin size.

Fig. 9-3-4

9-3-7. Installation

NOTE : For installation, at least 3 dimensions

should be kept free from obstacles (walls).

Fig. 9-3-5

Outdoor

unit

10 m

or less

A

B

Valve

cover

Fixing bolt arrangement of outdoor unit

Fig. 9-3-6

• Secure the outdoor unit with the fixing bolts

and nuts if the unit is likely to be exposed

to a strong wind.

• Use ø8 mm or ø10 mm anchor bolts and

nuts.

Drainage

Fig. 9-3-7

• Install the provided drain nipple in the hole

of the bottom plate.

• Perform proper drainage processing using

a drain hose sold separately or one on the

market. (Inner diameter : 16 mm)

• Do not use an ordinary hose on the market,

because it tends to get flat and as a result,

it prevents water from draining.

1. Piping connections to the outdoor unit should

be arranged in the sequence A, B, starting

from the bottom.

(For each piping connection, the gas pipe is

on the bottom and the liquid pipe is on the

top.)

2. When multiple indoor units are to be

connected to the outdoor unit, make the ends

of the pipes and wires from each indoor unit

to ensure that they will be connected to the

outdoor unit correctly.

(Problems caused by indoor units being

connected to the outdoor unit incorrectly are

very common in multiple-unit installations.)

3. The length and height difference of the

connecting pipes between the indoor and

outdoor units must be within the ranges

indicated below.

• Total piping length : Two room Multi (A + B)

= 30 m or less

• Minimum piping length : A or B

= 2 m or more

• Maximum indoor piping length :

A or B = 20 m or less

• Maximum piping height difference :

A or B = 10 m or less

• Maximum piping / height difference

between two rooms = 10 m or less

Fig. 9-3-8

4. If the outdoor unit is to be mounred on a wall,

make sure that the platform supporting it is

sufficiently strong.

The platform should be designed and

manufactured to maintain its strength over a

long period of time, and sufficient consider-

ation should be given to ensuring that the

outdoor unit will not fall.

5. When the outdoor unit is to be mounted high

on a wall, take particular care to ensure that

parts do not fall installer is protected.

6. When doing installation work on level ground,

it is usual to wiring and piping connections to

the indoor units. And/then make to the outdoor

unit.

However if outdoor work is difficult it is

possible instead to make changes to the

procedure.

For example by making adjustments to the

wiring and piping length on the inside (rather

than the outside).

How to remove the valve cover

1. Remove a screw of the valve cover.

2. Pull the valve cover downward.

Fig. 9-3-9