– 47 –

Half union

Flare nut

Externally

threaded side

Internally

threaded side

Use a wrench to secure.

Use a torque wrench to tighten.

Outdoor unit

Indoor unit

B

B UNIT

ø6,35

ø9,52

A

A UNIT

ø6,35

ø9,52

Flare at

indoor

unit side

Flare at

outdoor

unit side

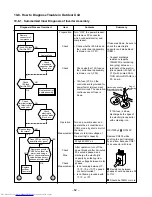

Tightening connection

Align the centers of the connecting pipes and

tighten the flare nut as far as possible with your

fingers. Then tighten the nut with a spanner and

torque wrench as shown in the figure.

CAUTION

• Do not apply excess torque. Otherwise,

the nut may crack depending on the

conditions.

(Unit : N·m)

• Tightening torque of flare pipe connections

Pressure of R410A becomes higher than that

of R22. (Approx. 1,6 times) Therefore, using a

torque wrench, tighten firmly the flare pipe

connecting sections which connect the indoor

and outdoor units up to the specified

tightening torque. Incorrect connections may

cause not only a gas leakage,

but also a trouble of the refrigeration cycle.

9-3-8. Evacuating

After the piping has been connected to all indoor

unit(s), you can perform the air purge together at

once.

AIR PURGE

Evacuate the air in the connecting pipes and

in the indoor unit using vacuum pump.

Do not use the refrigerant in the outdoor unit.

For details, see the manual of vacuum pump.

Use a vacuum pump

Be sure to use a vacuum pump with counter-flow

prevention function so that inside oil of the pump

does not flow backward into pipes of the air

conditioner when the pump stops. (If inside oil of

the vacuum pump enters into the air conditioner

which adopts R410A, a trouble of the refrigeration

cycle may be caused.)

1. Connect the charge hose from the manifold

valve to the service port of the gas side

packed valve.

2. Connect the charge hose to the port of

vacuum pump.

3. Open fully the low pressure side handle of the

gauge manifold valve.

4. Operate the vacuum pump to start for

evacuating.

Perform evacuating for about 15 minutes if the

total piping length is 30 meters. (15 minutes

for 30 meters) (assuming a pump capacity of

27 liters per minute.)

Then confirm that the pressure gauge reading

is –101 kPa ( –76 cmHg).

5. Close the low pressure side valve handle of

gauge manifold.

6. Open fully the valve stem of the packed

valves (both side of Gas and Liquid).

7. Remove the charging hose from the service

port.

8. Securely tighten the caps on the packed valves.

9. Execute above works from 1 to 8 on the each

connected indoor unit.

Packed valve handling precautions

• Open the valve stem all the way out; so not try

to open it beyond the stopper.

• Securely tighten the valve stem cap torque is

as follows :

Compound pressure gauge

Pressure gauge

Manifold valve

Handle Hi

(Keep full closed)

Charge hose

(For R410A only)

Vacuum pump adapter

for counter-flow prevention

(For R410A only)

Packed valve at liquid side

Packed valve at gas side

Service port

(Valve core (Setting pin))

Connecting

pipe

Handle Lo

Charge hose

(For R410A only)

–101kPa (–76cmHg)

Vacuum

pump

Gas side

(ø12,7 mm)

Gas side

(ø9,52 mm)

Liquid side

(ø6,35 mm)

Service port

50 to 62 N•m

(5,0 to 6,2 kgf•m)

33 to 42 N•m

(3,3 to 4,2 kgf•m)

14 to 18 N•m

(1,4 to 1,8 kgf•m)

14 to 18 N•m

(1,4 to 1,8 kgf•m)

Fig. 9-3-13

9-3-9. Electrical Work

For the air conditioner that has no power cord,

connect a power cord to it as mentioned below.

5mm

Terminal block

(Connecting cable)

Terminal block

(Power supply)

Connecting cable

(B unit)

Connecting cable

(A unit)

Cord clamp

Screw

Power cord

Earth line

Outer dia. of copper pipe

ø6,35 mm

ø9,52 mm

ø12,7 mm

Tightening torque

14 to 18 (1,4 to 1,8 kgf•m)

33 to 42 (3,3 to 4,2 kgf•m)

50 to 62 (5,0 to 6,2 kgf•m)

Fig. 9-3-10

Never apply refrigerating machine oil to

the flare surface.

Fig. 9-3-11

Fig. 9-3-12

Hexagon wrench is required.

Power

source

220–230–240

Single phase

50 Hz

Maximum

running

current

8,5 A

Fuse

rating

10A

Power

cord

2,0mm

2

(AWG-14)

or more

Fig. 9-3-14

How to wiring connection

1. Connect the connecting cable to the terminal

as identified with their respective matched

numbers on the terminal block of indoor and

outdoor unit. (1,0 mm

2

AWG 18 or more)

2. When connecting the connecting cable to the

outdoor unit terminal, prevent water coming in

the outdoor unit.

3. Insulate the unused cords (conductors) with

strip the sheath of connecting cable with PVC

tape.

Process them so that they do not touch any

electrical or metal parts.

4. For inter-unit wiring, do not use a cut wire

jointed to another on the way.

Use wires long enough to cover the entire

length.

CAUTION

• Wrong wiring connection may cause some

electrical parts burn out.

• Be sure to use the cord clamps specified

positions with attached to the product.

• Do not damage or scratch the conductive

core and inner insulator of power and inter-

connecting cables when peeling them.

• Be sure to comply with local codes on

running the wire from outdoor unit to indoor

unit (size of wire and wiring method etc.)

• Use the power cord and Inter-connecting

cable with specified thickness, specified

type, and protective devices specified.

Stripping length power cord and

connecting cable

Connecting

cable

Power cord

Earth line

Earth line

10

10

L N

30

10

30

40

10

40

1 2 3

Fig. 9-3-15