11

EN

EN

GL

ISH

This air conditioner must be grounded without fail.

Grounding is necessary not only to safeguard against the possibility of receiving an electric shock but also to absorb both the static,

which is generated by high frequencies and held in the surface of the outdoor unit, and noise since the air conditioner incorporates a

frequency conversion device (called an inverter) in the outdoor unit. If the air conditioner is not grounded, users may receive an

electric shock if they touch the surface of the outdoor unit and that unit is charged with static.

* The conventional leak detector for HCFC refrigerant (R22, etc.) cannot be used because its sensitivity for HFC refrigerant lowers to

approx. 1/40 of that manufactured exclusively for HFC refrigerant.

• Pressure of R410A becomes approx. 1.6 times that of R22. If

installation work has not completely finished, gas leaks may occur in

cases such as when pressure rises during operation.

• Check the flare nut connections, valve stem cap connections and

service port cap connections for gas leaks with a leak detector or

soap water.

Make sure that the wiring and piping for each room have the same alphabetical code (A, B).

Connect and secure the power cord.

Use the power cord/cables with thickness, type, and protective devices specified in this manual.

Insulate the unused cords (conductors) with PVC tape.

1.

Turn on the electrical power breaker.

2.

Operate the indoor unit in cooling mode.

3.

Start checks.

• Run the indoor unit in room A, and confirm cool air blows out.

• Confirm the indoor unit in room B is not running. (Also check at this time that refrigerant, which can be heard, is not flowing.)

• Stop operation of the indoor unit in room A and execute the same checks on the indoor unit in room B.

5 GROUNDING

6 CHECK AND TEST OPERATION

For R410A, use the leak detector exclusively manufactured for HFC refrigerant (R410A, R134a, etc.)

CAUTION

• Use a circuit breaker of a type that is not tripped by shock waves.

• Incorrect/incomplete wiring will cause electrical fires or smoke.

• Prepare the power source for exclusive use with the air conditioner.

• Proceed as follows when connecting the product to the mains power.

• Connection to fixed wiring:

A switch or circuit breaker which disconnects all poles and has a contact separation of at least 3 mm must be incorporated

into the fixed wiring.

Utilize only approved short circuit breakers and switches.

* (A breaker having sensitivity of approximately 0.1 second or less and capacity of approximately 30 mA is usually used.)

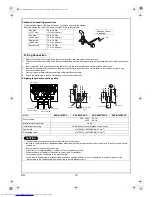

Miswiring (Mis-piping) Check

Flare nut connections

(Indoor unit)

• Flare nut connections (Outdoor unit)

• Valve stem cap connection

• Service port cap connection

OutdoorInstallation.book Page 11 Wednesday, February 1, 2006 9:12 AM