– 68 –

10. SETUP AT LOCAL SITE AND OTHERS

10-1. Indoor Unit

10-1-1. Test Run Setup on Remote Controller

<Wired remote controller>

1. When pushing button on the remote controller for 4 seconds or more, “TEST” is displayed on LC display.

Then push

button.

• “TEST” is displayed on LC display during operation of Test Run.

• During Test Run, temperature cannot be adjusted but air volume can be selected.

• In heating and cooling operation, a command to fix the Test Run frequency is output.

• Detection of trouble is performed as usual. However, do not use this function except case of Test Run

because it applies load on the unit.

2. Use either heating or cooling operation mode for [TEST].

NOTE

: The outdoor unit does not operate after power has been turned on or for approx. 3 minutes after

operation has stopped.

3. After a Test Run has finished, push button again and check that [TEST] on LC display has gone off.

(To prevent a continuous test run operation, 60-minutes timer release function is provided to this remote

controller.)

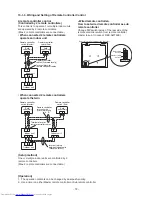

<Wireless remote controller>

In case of wireless remote controller

1

When TEMPORARY button is pushed for 10 seconds or more, “Pi!” sound is heard and the

operation changes to a forced cooling operation.

After approx. 3 minutes, a cooling operation starts forcedly.

Check cool air starts blowing. If the operation does not start, check wiring again.

2

To stop a test operation, push TEMPORARY button once again (Approx. 1 second).

• Check wiring / piping of the indoor and outdoor units in forced cooling operation.

TEMPORARY button