– 106 –

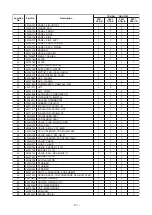

No. Part name

Procedure

Remarks

h

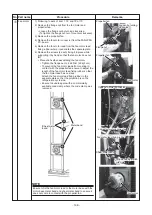

Fan motor

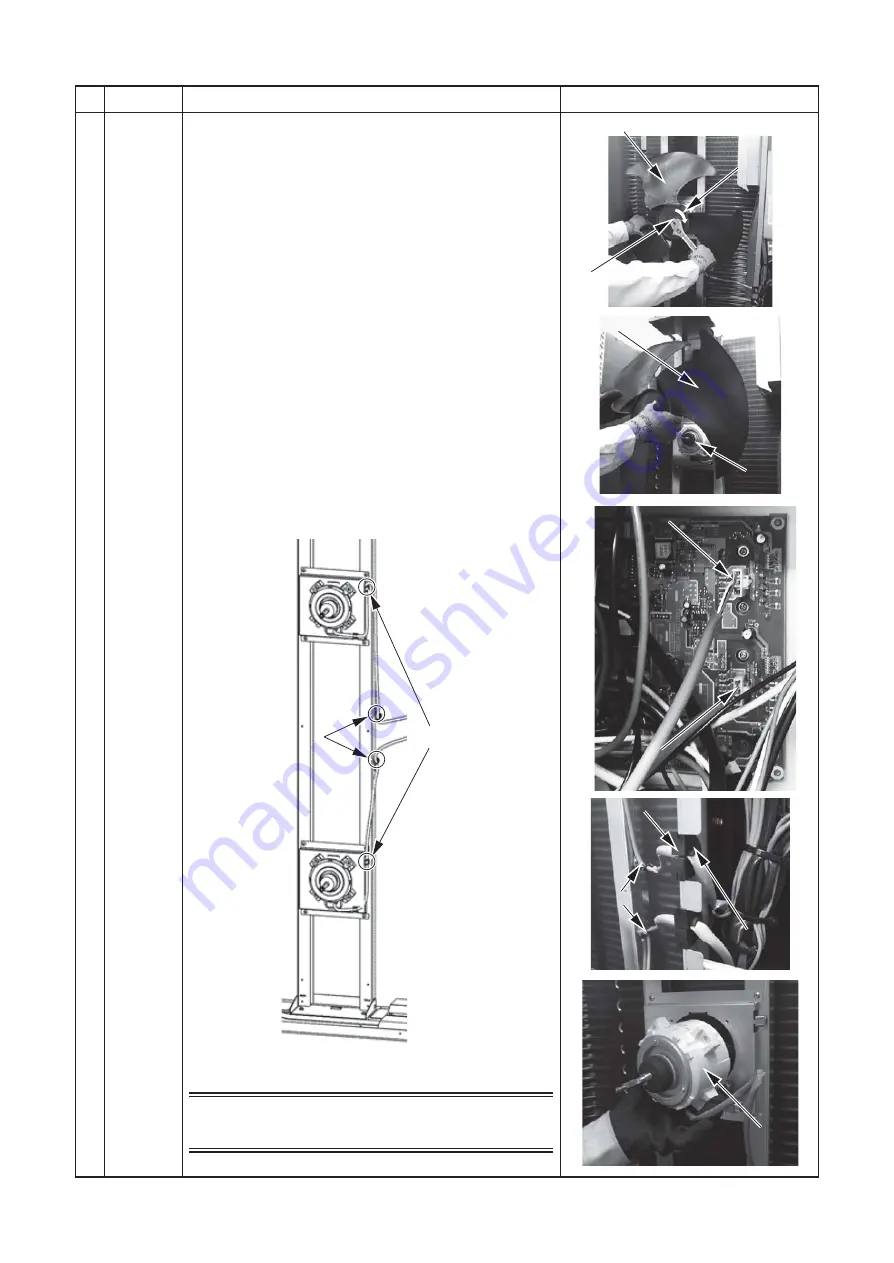

1) Following to work of item 1,

d

and

e

of

c

.

2) Remove the flange nut from the fan motor and

propeller fan.

• Loosen the flange nut by turning clock wise.

(To tighten the flange nut, turn it counter clockwise)

3) Remove the propeller fan.

4) Remove the fan motor connector from the FAN-IPDU

P.C. board.

5) Remove the fan motor lead from the fan motor lead

fixing rubber where it penetrates the separate plate.

6) Remove the screws (4 each) fixing it in place while

supporting it by hand so that the fan motor does not

fall.

∗

Precautions when assembling the fan motor

• Tighten the flange nut to 4.95 N•m (50 kgf·cm).

• To prevent the fan motor leads from coming in

contact with the propeller fan ensure to adjust the

length of the fan motor lead fixing rubber so that

the fan motor lead has no slack.

Attach the fan motor lead fixing rubber to the

separate plate so that the projection is on the

refrigeration cycle side.

• Ensure to bundle again with a commercially

available code clamp where the code clamp was

removed.

Propeller fan

Propeller fan

Loosen by turning

Loosen by turning

clockwise

clockwise

Flange nut

Fan motor

Fan motor

Fan motor

Fan motor

Upper fan motor connector

Upper fan motor connector

Lower fan motor connector

Lower fan motor connector

Fan motor lead fixing rubber

Fan motor lead fixing rubber

Sheet metal band

Sheet metal band

Protrusion/refrigeration

Protrusion/refrigeration

cycle side

cycle side

Loosen by turning

clockwise

Fan motor

Fan motor

Upper fan motor connector

Lower fan motor connector

Fan motor lead fixing rubber

Sheet metal band

Protrusion/refrigeration

cycle side

Metal band

Sheet metal

Sheet metal

band

band

Sheet metal

band

NOTE

Ensure to fix the fan motor lead to the motor base with the

motor base metal band and sheet metal band to ensure it

does not come in contact with the propeller fan.