– 14 –

Optional installation parts

(Locally procured)

Refrigerant piping connection

CAUTION

Take note of these 4 important points below for

piping work.

1.Keep dust and moisture away from inside the

connecting pipes.

2.Tightly connect the connection between pipes and

the unit.

3.Evacuate the air in the connecting pipes using a

VACUUM PUMP.

4.Check for gas leaks at connection points.

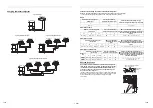

Piping connection

Flaring

1

Cut the pipe with a pipe cutter.

Be sure to remove burrs that may cause a gas

leak.

2

Insert a flare nut into the pipe, and then flare

the pipe.

Use the flare nuts supplied with the air conditioner

or those for R32.

Insert a flare nut into the pipe, and flare the pipe.

Use the flare nuts supplied with the air conditioner

or flare nuts for R32 or R410A.

However, the conventional tools can be used by

adjusting the projection margin of the copper pipe.

Projection margin in flaring: B (Unit: mm)

Rigid (Clutch type)

Flaring dia. size: A (Unit: mm)

CAUTION

• Do not scratch the inner surface of the flared part

when removing burrs.

• Flare processing under the condition of scratches

on the inner surface of flare processing part will

cause refrigerant gas leak.

• Check that the flared part is not scratched,

deformed, stepped, or flattened, and that there are

no chips adhered or other problems, after flare

processing.

• Do not apply refrigerating machine oil to the flare

surface.

Parts name

Q’ty

A

Refrigerant piping

Liquid side: Dia. 12.7 mm

Gas side: Dia. 28.6 mm

One each

B

Socket: Dia. 28.6 - Dia. 28.6 mm

1

C

Pipe insulating material

(polyethylene foam, 10 mm thick)

1

D

Putty, PVC tape

One each

Liquid side

Outer diameter

Thickness

Dia. 12.7 mm

0.8 mm

Gas side

Outer diameter

Thickness

Dia. 28.6 mm

1.0 mm (half hard)

Outer dia. of

copper pipe

R32 or R410A

tool used

Conventional

tool used

12.7

0 to 0.5

1.0 to 1.5

19.1

Outer dia. of copper pipe

A +0

–0.4

12.7

16.6

19.1

24.0

B

A

Connecting the Gas Side Pipe

REQUIREMENT

• Be sure to use the Dia. 19.1 mm pipe and joint

provided as accessories of the outdoor unit to

connect the gas side Dia. 19.1 mm pipe and Dia.

28.6 mm pipe.

• When leading out the pipes toward the front, to one

of the sides or toward the rear, use the Dia.

19.1 mm pipe and elbow provided as accessories of

the outdoor unit, and adjust the bending direction.

Cut the Dia. 19.1 mm pipe to the required length

before using it.

1. Align the provided Dia. 19.1 mm pipe with the pipe

lead-out direction, and shape it so that its end comes

out from the outdoor unit.

2. On the outside of the outdoor unit, use the provided

joints, and braze the Dia. 19.1 mm pipe and Dia.

28.6 mm pipe.

REQUIREMENT

• Before proceeding to brazing the refrigerant pipe,

be sure to pass nitrogen through the pipe to prevent

oxidation inside it. If nitrogen is not passed through

the pipe, the refrigerating cycle may become

clogged by oxidized scales.

Tightening of connecting part

1

Align the centers of the connecting pipes and

fully tighten the flare nut with your fingers.

Then fix the nut with a wrench as shown in the

figure and tighten it with a torque wrench.

2

As shown in the figure, be sure to use two

wrenches to loosen or tighten the flare nut of

the valve on the gas side. If you use a single

crescent, the flare nut cannot be tightened to

the required tightening torque.

On the other hand, use a single crescent to loosen

or tighten the flare nut of the valve on the liquid

side.

Brazing

Joint: Dia. 19.1 – Dia. 25.4 mm

(accessory)

Joint: Dia. 25.4 – Dia. 28.6 mm

(accessory)

Socket: Dia. 28.6 - Dia. 28.6 mm

(procured locally)

Dia. 28.6 mm pipe

(procured locally)

Brazing

Brazing

(Unit: N•m)

Outer dia. of copper pipe

Tightening torque

12.7 mm (diam.)

50 to 62

19.1 mm (diam.)

100 to 120

Cap

Loosened

Cover

Piping valve

Tightened

Flare nut

Valve at gas side

27-EN

28-EN

Summary of Contents for RAV-GM2241AT8-E1

Page 31: ...EB99844301 DH91308001 ...