– 27 –

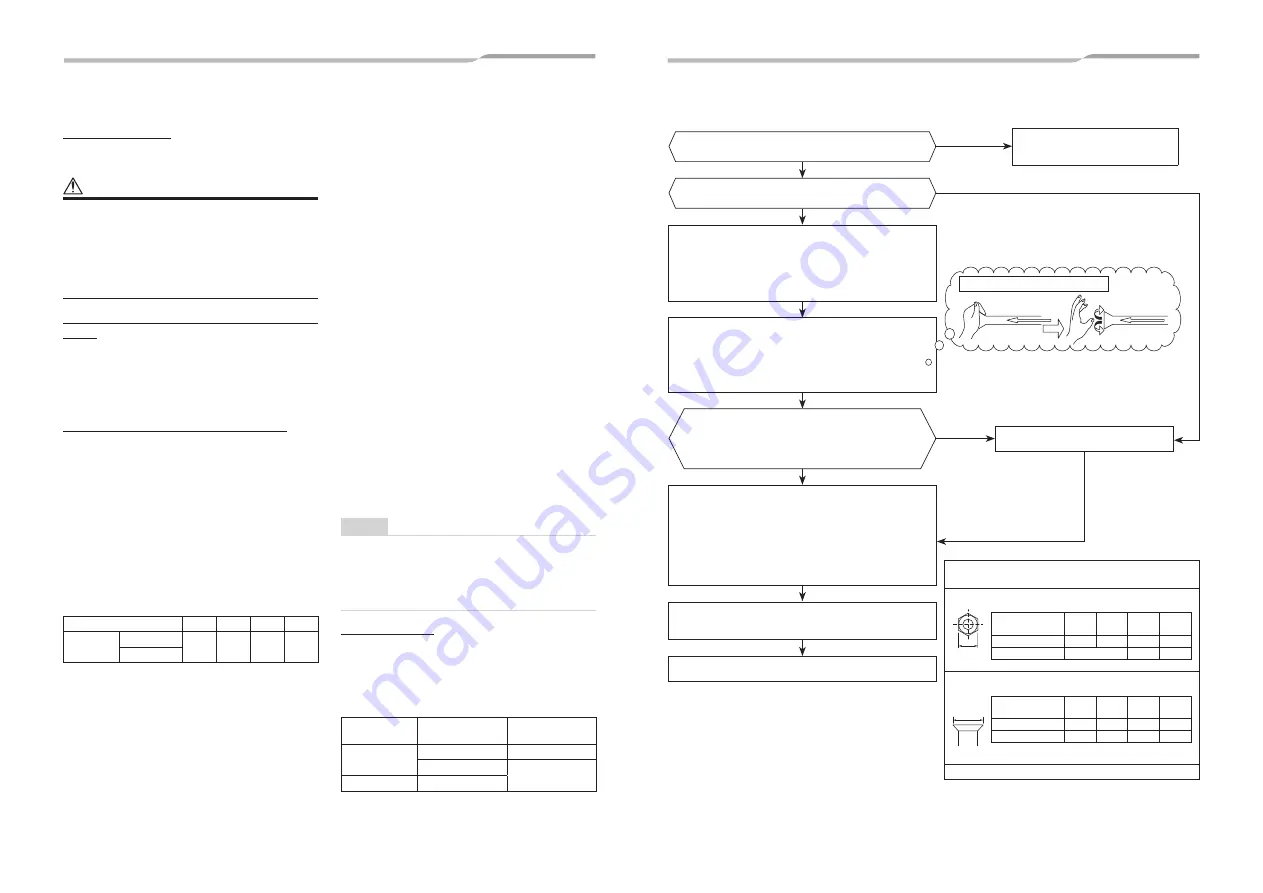

Are there scratches or dents on the existing pipes?

Is it possible to operate the existing air conditioner?

y

After the existing air conditioner is operated in

cooling mode for approx. 30 minutes or longer,*

recover the refrigerant.

y

For cleaning the pipes and recovering oil

y

Refrigerant recovery: Pump down method

y

Remove the existing air conditioner from the piping

and carry out

fl

ushing (nitrogen pressure 0.5 MPa)

to remove any remains inside of the pipe.

Note:

In case of twin pipes, also be sure to

fl

ush the

branching pipe.

Connect the indoor / outdoor units to the existing

pipe.

y

Use a

fl

are nut attached to the main unit for the

indoor / outdoor units. (Do not use the

fl

are nut of

the existing pipe.)

y

Re-machine the

fl

are machining size to size for

R32.

y

(Airtight test), Vacuum dry, Refrigerant charge, Gas

leak check

Test run

Was largely discolored oil or a large quantity

of remains discharged? (When the oil deteriorates,

the color of the oil changes to a muddy or

black color.)

Existing pipes: Cannot be used.

y

Use new pipes.

Clean the pipes or use new pipes.

Piping necessary to change the

fl

are nut / machining

size due to pipe compression

1) Flare nut width: H

H

(mm)

Copper pipe

outer diameter

Ø6.4

Ø9.5

Ø12.7

Ø15.9

For R32, R410A

17

22

26

29

For R22

Same as above

24

27

2) Flare machining size: A

A

(mm)

Copper pipe

outer diameter

Ø6.4

Ø9.5

Ø12.7

Ø15.9

For R32, R410A

9.1

13.2

16.6

19.7

For R22

9.0

13.0

16.2

19.4

Becomes a little larger for R32

Do not apply refrigerator oil to the

fl

are surface.

(If there is discharge of remains, it is judged that a

large quantity of remains are present.)

YES

YES

NO

NO

NO

YES

Nitrogen gas pressure 0.5 MPa

13

Appendix

Work instructions

The existing R22 and R410A piping can be reused for

inverter R32 product installations.

WARNING

Con

fi

rming the existence of scratches or dents on

the existing pipes and con

fi

rming the reliability of

the pipe strength are conventionally referred to the

local site.

If the speci

fi

ed conditions can be cleared, it is

possible to update existing R22 and R410A pipes

to those for R32 models.

Basic conditions needed to reuse existing

pipes

Check and observe the presence of three conditions in

the refrigerant piping works.

1.

Dry

(There is no moisture inside of the pipes.)

2.

Clean

(There is no dust inside of the pipes.)

3.

Tight

(There are no refrigerant leaks.)

Restrictions for use of existing pipes

In the following cases, the existing pipes should

not be reused as they are. Clean the existing pipes

or exchange them with new pipes.

1. When a scratch or dent is heavy, be sure to use

new pipes for the refrigerant piping works.

2. When the existing pipe thickness is thinner than the

speci

fi

ed “Pipe diameter and thickness,” be sure to

use new pipes for the refrigerant piping works.

y

The operating pressure of refrigerant is high.

If there is a scratch or dent on the pipe or a

thinner pipe is used, the pressure strength may be

inadequate, which may cause the pipe to break in

the worst case.

* Pipe diameter and thickness (mm)

Pipe outer diameter

Ø6.4

Ø9.5 Ø12.7 Ø15.9

Thickness

R32, R410A

0.8

0.8

0.8

1.0

R22

3. When the outdoor unit was left with the pipes

disconnected, or the gas leaked from the pipes and

the pipes were not repaired and re

fi

lled.

y

There is the possibility of rain water or air,

including moisture, entering the pipe.

4. When refrigerant cannot be recovered using a

refrigerant recovery unit.

y

There is the possibility that a large quantity of dirty

oil or moisture remains inside the pipes.

5. When a commercially available dryer is attached to

the existing pipes.

y

There is the possibility that copper green rust has

been generated.

6. When the existing air conditioner is removed after

refrigerant has been recovered.

Check if the oil is judged to be clearly different from

normal oil.

y

The refrigerator oil is copper rust green in color:

There is the possibility that moisture has mixed

with the oil and rust has been generated inside

the pipe.

y

There is discolored oil, a large quantity of residue,

or a bad smell.

y

A large quantity of shiny metal dust or other wear

residue can be seen in the refrigerant oil.

7. When the air conditioner has a history of the

compressor failing and being replaced.

y

When discolored oil, a large quantity of residue,

shiny metal dust, or other wear residue or mixture

of foreign matter is observed, trouble will occur.

8. When temporary installation and removal of the air

conditioner are repeated such as when leased etc.

9. If the type of refrigerator oil of the existing air

conditioner is other than the following oil (Mineral

oil), Suniso, Freol-S, MS (Synthetic oil), alkyl

benzene (HAB, Barrel-freeze), ester series, PVE

only of ether series.

y

The winding-insulation of the compressor may

deteriorate.

NOTE

The above descriptions are results have been

con

fi

rmed by our company and represent our views on

our air conditioners, but do not guarantee the use of

the existing pipes of air conditioners that have adopted

R32 in other companies.

Curing of pipes

When removing and opening the indoor or outdoor unit

for a long time, cure the pipes as follows:

y

Otherwise rust may be generated when moisture or

foreign matter due to condensation enters the pipes.

y

The rust cannot be removed by cleaning, and new

pipes are necessary.

Placement

location

Term

Curing manner

Outdoors

1 month or more

Pinching

Less than 1 month

Pinching or taping

Indoors

Every time

54-EN

53-EN

Summary of Contents for RAV-GM901BTP-E

Page 29: ... 28 56 EN 55 EN ...