- 81 -

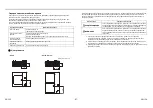

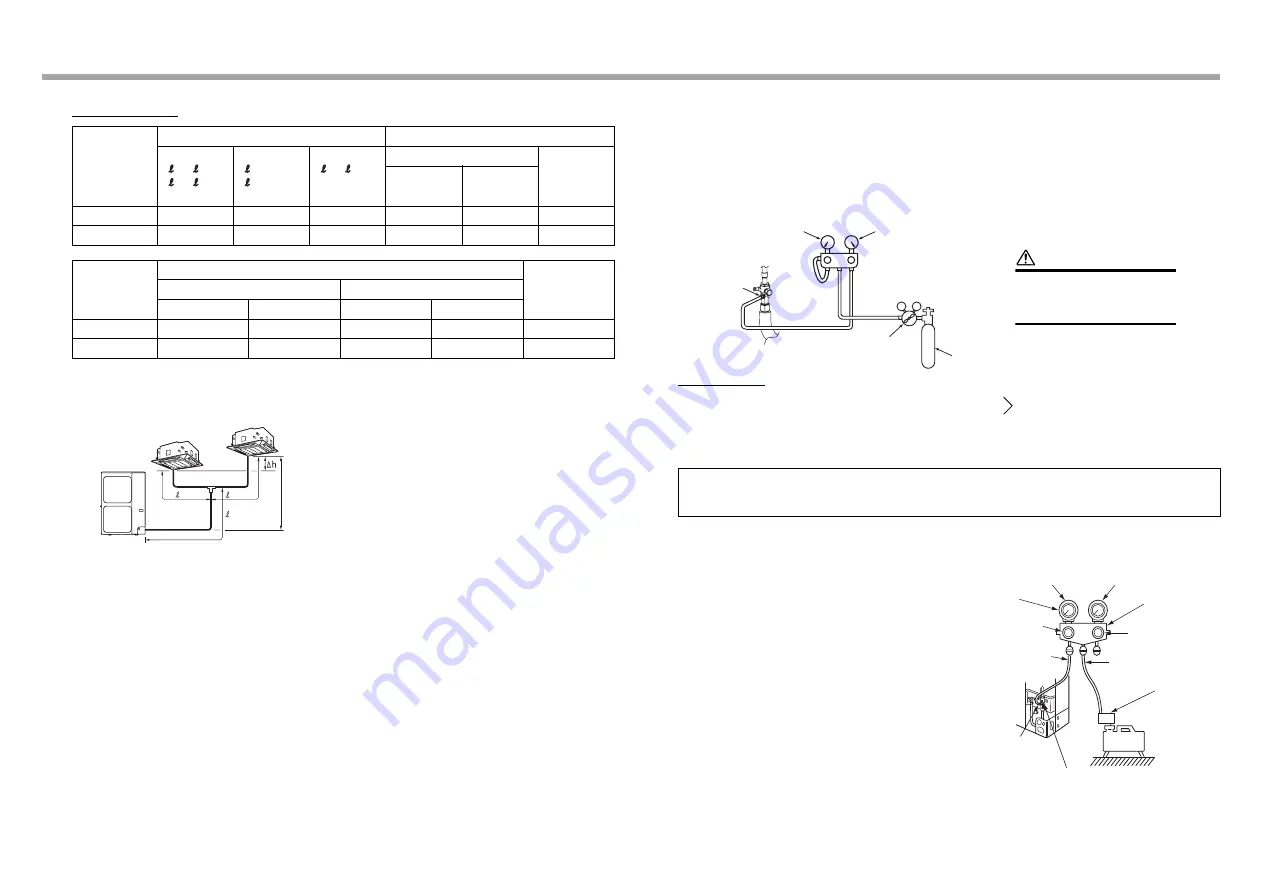

Simultaneous twin

Outdoor unit

Allowable pipe length (m)

Height difference (m)

Total length

•

1

+

2

•

1

+

3

Maximum

Branch piping

•

2

•

3

Maximum

Branch piping

•

3

–

2

Maximum

Indoor-outdoor H

Indoor-indoor

(

Δ

h)

Indoor unit:

Upper

Outdoor unit:

Upper

GP80, 110

50

15

10

30

30

0.5

GP140

50

15

10

30

30

0.5

Outdoor unit

Pipe diameter (mm)

Number of bent

portions

Main pipe

Branch piping

Gas side

Liquid side

Gas side

Liquid side

GP80, 110

15.9

9.5

12.7

6.4

10 or less

GP140

15.9

9.5

15.9

9.5

10 or less

2

3

H

1

Figure of simultaneous twin

Indoor unit

Outdoor unit

Indoor unit

6

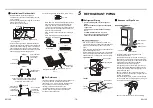

AIR PURGING

Airtight Test

After completing the refrigerant piping work, perform an airtight test. Connect a nitrogen gas cylinder and pressurize

the pipes with nitrogen gas as follows to conduct the airtight test.

Gas leak check

* After the airtight test is completed, evacuate the nitrogen gas.

Air Purge

With respect to the preservation of the terrestrial

environment, adopt “Vacuum pump” to purge air

(Evacuate air in the connecting pipes) when installing the

unit.

• Do not discharge the refrigerant gas to the

atmosphere to preserve the terrestrial environment.

• Use a vacuum pump to discharge the air (nitrogen,

etc.) that remains in the set. If air remains, the capacity

may decrease.

For the vacuum pump, be sure to use one with a

backflow preventer so that the oil in the pump does not

backflow into the pipe of the air conditioner when the

pump stops.

(If oil in the vacuum pump is put in an air conditioner

including R32, it may cause trouble with the refrigeration

cycle.)

Step 1....Pressurize to

0.5 MPa

(5 kg/cm

2

G) for 5 minutes or longer.

Major leaks can be discovered.

Step 2....Pressurize to

1.5 MPa

(15 kg/cm

2

G) for 5 minutes or longer.

Step 3....Pressurize to

4.15 MPa

(42 kg/cm

2

G) for 24 hours. ................ Micro leaks can be discovered.

(However, note that when the ambient temperature differs during pressurization and after 24 hours, the pressure will

change by approximately 0.01 MPa (0.1 kg/cm

2

G) per 1°C, so this should be compensated.)

If the pressure drops in steps 1 through 3, check the connections for leakage.

Check for leaks with foaming liquid, etc., take steps to fix the leaks such as brazing the pipes again and tightening

the flare nuts, and then perform the airtight test again.

V

L

V

H

Charge port

Low pressure gauge

High pressure gauge

Gauge manifold

Pressure reducing

valve

Nitrogen gas

CAUTION

Never use oxygen, flammable gas,

or noxious gas for the airtight test.

Pressure gauge

Gauge manifold valve

Handle High

(Keep fully closed)

Compound pressure gauge

Charge hose

(For R32 or R410A

only)

Vacuum

pump adapter

for backflow

prevention

(For R32 or

R410A only)

–101 kPa

(–76 cmHg)

Handle Low

Charge hose

(For R32 or R410A

only)

Charge port

(Valve core

(Setting pin))

Packed valve at gas side

Vacuum

pump

EN-161

EN-162

Summary of Contents for RAV-GP1101AT-E

Page 95: ... 94 MEMO EN 187 EN 188 ...

Page 96: ...EB99845801 ...