– 65 –

Check

code

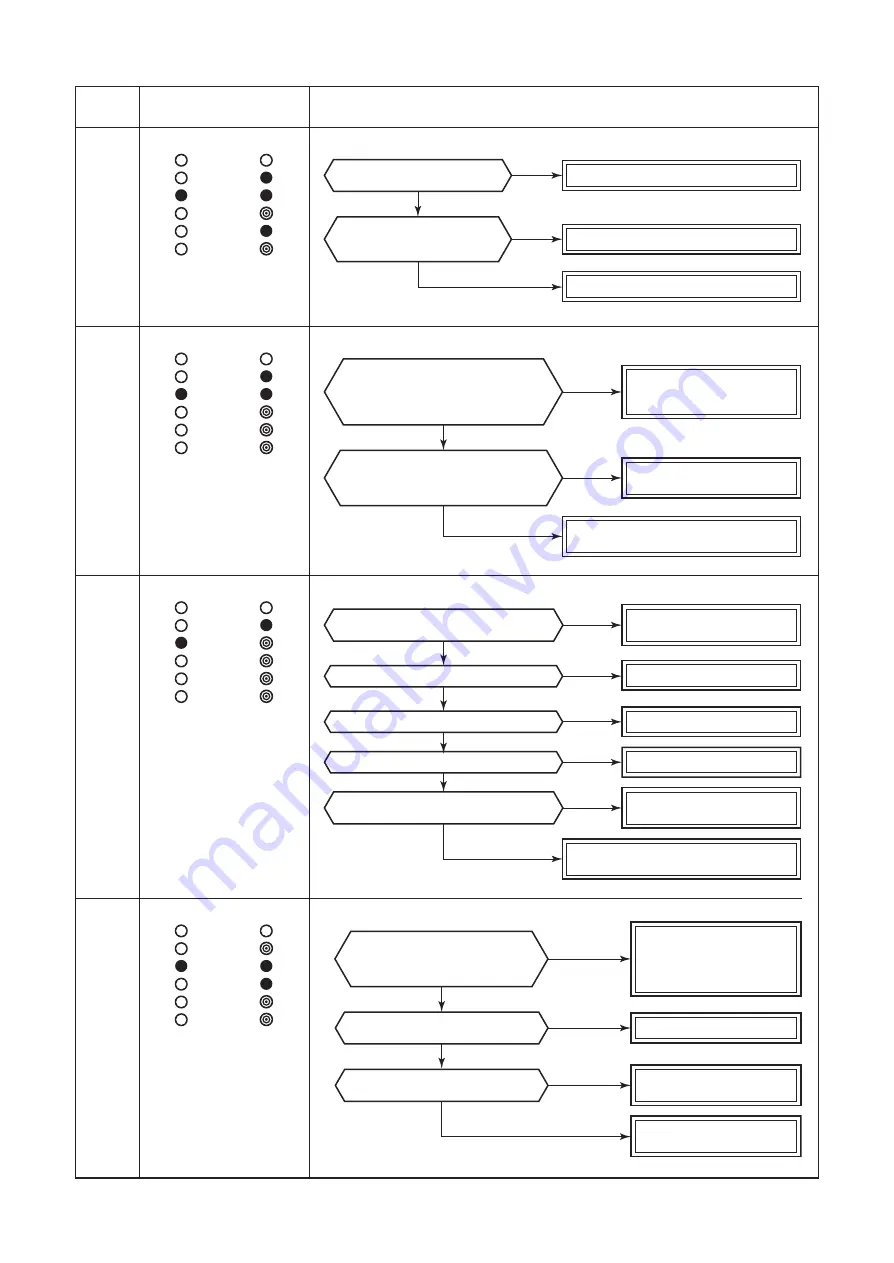

[P05]

[P15]

Outdoor

LED display

<Display 1> <Display 2>

<Display 1> <Display 2>

Check and troubleshooting

(Item without special mention Indicates part of outdoor unit.)

[Power supply trouble (Voltage trouble)]

[Gas leak detection]

Confirm electric con

s

tr

u

ction, etc.

Replace o

u

tdoor P.C.

b

oard (MCC-1600).

Correct wiring.

NO

YES

YES

NO

I

s

there open pha

s

e

of the power

su

pply?

I

s

power

su

pply

voltage normal?

(AC342 to 457V)

[P07]

<Display 1> <Display 2>

[Heat sink overheat trouble]

Replace o

u

tdoor P.C.

b

oard (MCC-1596).

Remove

b

locking matter.

Correct

s

hort-circ

u

it.

NO

NO

YES

YES

Apply radiation grea

s

e

to o

b

jective part.

Retightening of

s

crew

s

.

Doe

s

s

omething

b

lock the

ventilation aro

u

nd the heat

s

ink?

Doe

s

s

omething

b

lock air flow from the fan?

(Short-circ

u

it, etc.)

Are radiation grea

s

e properly applied?

Are the

s

crew

s

of the motor drive element

Q201 on the o

u

tdoor P.C.

b

oard (MCC-1596),

the rear

s

ide of Q201 correctly?

Open valve f

u

lly.

Correct and replace piping.

Correct connector.

Sen

s

or tro

ub

le

→

Replace

Replace o

u

tdoor P.C.

b

oard (MCC-1599).

Replace PMV.

Repair tro

ub

le po

s

ition.

Recharge refrigerant.

A

b

normality

OK

NO

YES

YES

YES

NO

NO

YES

NO

I

s

there cr

us

hed pipe?

I

s

valve f

u

lly opened?

I

s

PMV normal?

Check temp.

s

en

s

or.

TD

s

en

s

or CN603, TS

s

en

s

or CN600

I

s

there ga

s

leak?

I

s

there refrigerant

s

hortage?

Replace o

u

tdoor P.C.

b

oard.

Replace coil of 4-way valve.

Temperat

u

re

s

en

s

or check

TE

s

en

s

or CN601

TS

s

en

s

or CN600

Indoor TC

s

en

s

or

Tro

ub

le

→

Correct and repair

Replace 4-way valve.

YES

YES

NO

NO

A

b

normality

OK

Check operation of

o

u

tdoor I/F (CDB) P.C.

b

oard.

I

s

power

su

pplied

to 4-way valve coil?

I

s

operation of

4-way valve normal?

(Check pipe temp., etc. in

cooling/heating operation.)

[P19]

<Display 1> <Display 2>

[4-way valve inverse trouble]