20-EN

19-EN

– 10 –

EN

4

Installation conditions

Before installation

Be sure to prepare to the following items before

installation.

Length of refrigerant pipe

Length of refrigerant pipe connected to

Indoor / Outdoor unit

5 to 30 m

y

Do not connect a refrigerant pipe that is shorter than

5 m

.

This may cause a malfunction of the compressor or

other devices.

Airtight test

1. Before starting an airtight test, further tighten the

spindle valves on the gas and liquid sides.

2. Pressurize the pipe with nitrogen gas charged from

the service port to the design pressure (4.29 MPa)

to conduct an airtight test.

3. After the airtight test is completed, evacuate the

nitrogen gas.

Air purge

y

To purge air, use a vacuum pump.

y

Do not use refrigerant charged in the outdoor unit to

purge air. (The air purge refrigerant is not contained

in the outdoor unit.)

Electrical wiring

y

Be sure to

fi

x the power wires and Indoor / Outdoor

connecting wires with clamps so that they do not

come into contact with the cabinet, etc.

Earthing

WARNING

Make sure that proper earthing is provided.

Improper earthing may cause an electric shock. For

details on how to check earthing, contact the dealer

who installed the air conditioner or a professional

installation company.

y

Proper earthing can prevent charging of electricity

on the outdoor unit surface due to the presence of a

high frequency in the frequency converter (inverter)

of the outdoor unit, as well as prevent electric shock.

If the outdoor unit is not properly earthed, you may

be exposed to an electric shock.

y

Be sure to connect the earth wire. (grounding

work)

Incomplete grounding can cause an electric shock.

Do not connect ground wires to gas pipes, water

pipes, lightning rods or ground wires for telephone

wires.

Test run

Turn on the leakage breaker at least 12 hours before

starting a test run to protect the compressor during

startup.

CAUTION

Incorrect installation work may result in a malfunction

or complaints from customers.

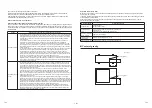

Bender

Bending pipes

Conventional tools (R410A)

Refrigerant recovery equipment

Refrigerant recovery

Conventional tools (R32 or R410A)

Torque wrench

Tightening

fl

are nuts

Conventional tools (R410A)

Pipe cutter

Cutting pipes

Conventional tools (R410A)

Refrigerant cylinder

Charging refrigerant

Prepared newly (Use for R32 only)

Welding machine and nitrogen

cylinder

Welding pipes

Conventional tools (R410A)

Electronic refrigerant charging

scale

Charging refrigerant

Conventional tools (R32 or R410A)

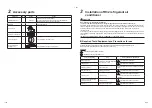

Refrigerant piping

R32 refrigerant

CAUTION

y

Incomplete

fl

aring may cause refrigerant gas leakage.

y

Do not re-use

fl

ares. Use new

fl

ares to prevent refrigerant gas leakage.

y

Use

fl

are nuts that are included with the unit. Using different

fl

are nuts may cause refrigerant gas leakage.

Use the following item for the refrigerant piping.

Material : Seamless phosphorous deoxidized copper pipe.

Ø9.52 Wall thickness 0.8 mm or more

Ø15.88 Wall thickness 1.0 mm or more

REQUIREMENT

When the refrigerant pipe is long, provide support brackets at intervals of 2.5 to 3 m to clamp the refrigerant pipe.

Otherwise, abnormal sound may be generated.