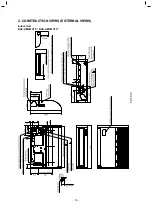

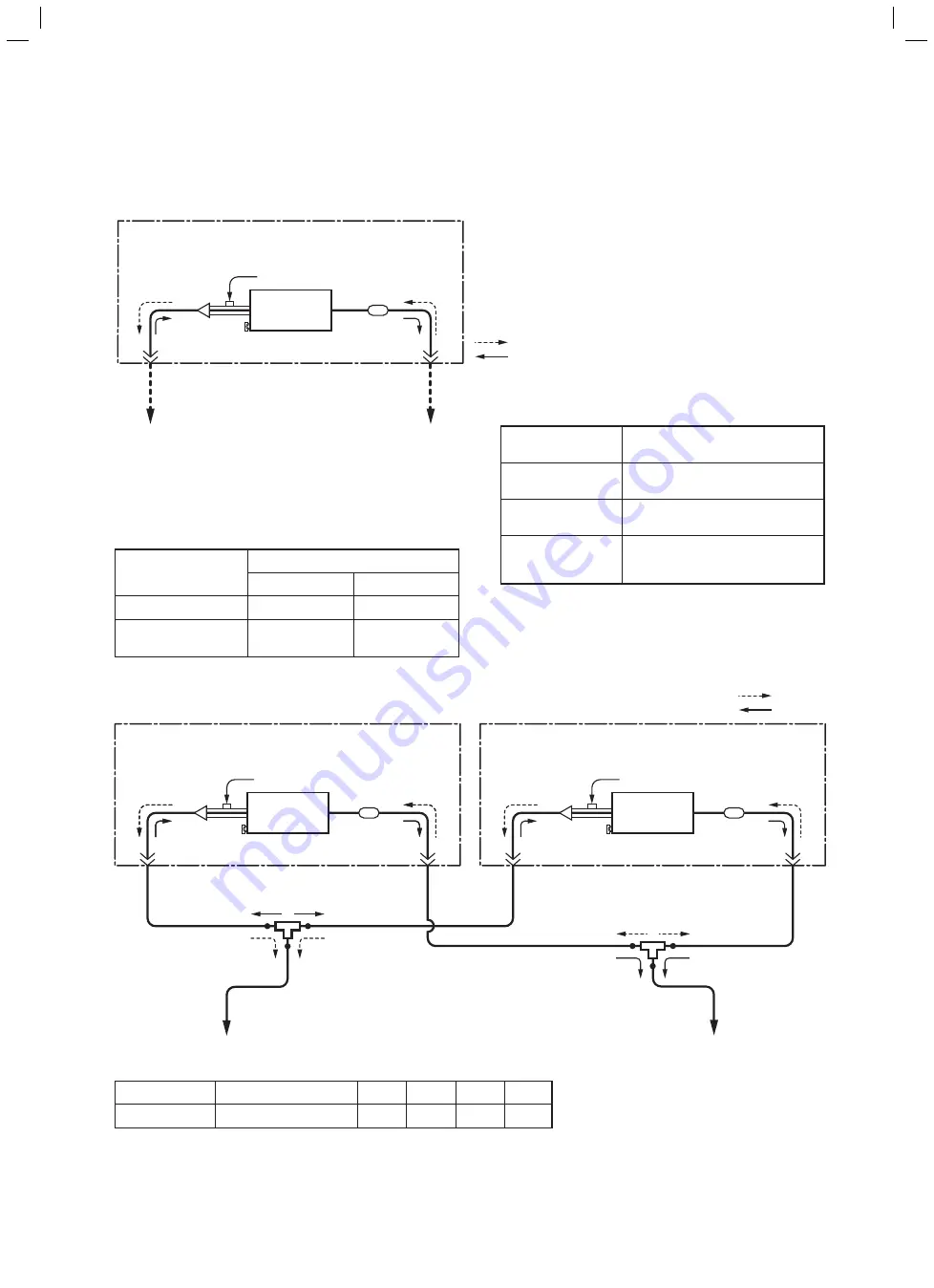

(Indoor unit A)

Liquid side

(Outer dia : ØA)

Liquid side

(Outer dia : ØC)

Gas side

(Outer dia : ØB)

Distributor

(Strainer incorporated)

Strainer

TCJ sensor

TC sensor

Heat

exchanger

To outdoor unit

Branch pipe

(Indoor unit B)

Liquid side

(Outer dia : ØA)

Liquid side

(Outer dia : ØD)

Gas side

(Outer dia : ØB)

Distributor

(Strainer incorporated)

Strainer

TCJ sensor

TC sensor

To outdoor unit

Branch pipe

Heat

exchanger

Heating

Cooling

(Indoor unit)

Liquid side

(Outer dia : ØB)

Gas side

(Outer dia : ØA)

Distributor

(Strainer incorporated)

Strainer

Heating

Cooling

TCJ sensor

TC sensor

Heat

exchanger

To outdoor unit

To outdoor unit

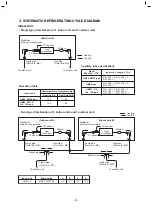

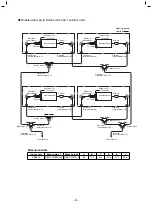

• Single type (Combination of 1 indoor unit and 1 outdoor unit)

• Twin type (Combination of 2 indoor units and 1 outdoor unit)

Indoor unit

H

M56

× 2

Branch pipe

RBC-TWP30E2

A

B

C

D

6.4

12.7

9.5

15.9

Dimension table

Indoor unit

H

M

40,

H

M56

type

Outer diameter of refrigerant pipe

Gas side ØA

Liquid side ØB

12.7

6.4

H

M80,

90,

110

140, 160

type

15.9

9.5

Capillary tube specifications

Model

RAV-

H

M

∗∗∗

CTP

∗

H

M40,

H

M56

type

H

M80 type

H

M

901,

110,

140, 160

type

Inner dia. × Length × Q’ty

Ø2 × 300 × 1, Ø2 × 350 × 1

Ø2 × 800 × 1

300

Ø2 × 400 × 1

Ø2 ×

× 1, Ø2 × 350 × 2

Ø2 × 150 × 1, Ø2 × 200 × 2

Ø2 × 250 × 1, Ø2 × 300 × 1

Ø2 × 350 × 1, Ø2 × 1000 × 1

3

.

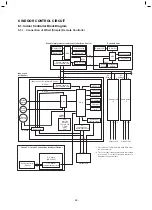

SYSTEMATIC REFRIGERATING CYCLE DIAGRAM

Indoor Unit

- 21 -